Cemented carbide is widely used in electronic communications manufacturing. Here are some specific applications:

1. High-speed cutting: Carbide has extremely high hardness and wear resistance and is suitable for high-speed cutting. In the field of electronic communication manufacturing, cemented carbide is often used to manufacture conductive parts such as terminals, plugs, and connectors. By using carbide cutting tools, various materials such as aluminum, copper, plastic and rubber can be effectively cut while avoiding tool wear and breakage, ensuring the quality and efficiency of processing.

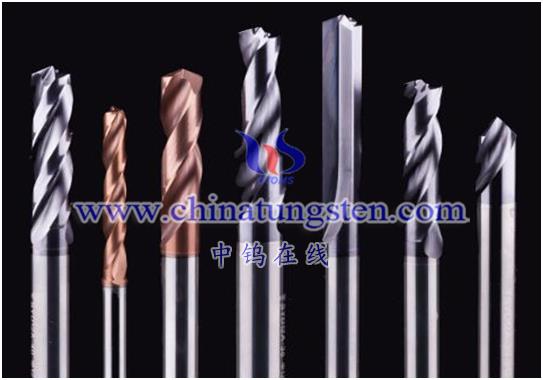

2. Drilling: Carbide has extremely high hardness and wear resistance and is suitable for high-precision hole processing. In the field of electronic communication manufacturing, cemented carbide is often used to manufacture various high-precision parts, such as electronic switches, shielding boxes, etc. By using carbide drill bits, high precision and efficiency in drilling can be achieved while avoiding wear and breakage of the drill bit, ensuring the quality and accuracy of the hole.

3. Manufacturing of wear-resistant parts: A large number of wear-resistant parts, such as bearings, bushings, gears, etc., are required in the manufacturing process of electronic communications. Because carbide has excellent wear resistance and high strength, it can be used to manufacture these wear-resistant parts. The use of parts made of cemented carbide can effectively improve the efficiency and life of the equipment and reduce maintenance costs.

4. Micro-tool manufacturing: A large number of micro-tools are used in the electronic communications manufacturing process, such as screwdrivers, wrenches, etc. Carbide can be used to make these micro-tools due to its high hardness and strength. Using micro-cutting tools made of carbide can improve tool life and safety and reduce production costs.

In short, cemented carbide is widely used in electronic communications manufacturing, involving high-speed cutting, drilling, wear-resistant parts manufacturing and micro-tool manufacturing. These applications benefit from the excellent properties of cemented carbide, such as high hardness, wear resistance, strength and corrosion resistance, making it one of the important materials in electronic communications manufacturing. With the continuous development and innovation of electronic communication technology, the application scope of cemented carbide in electronic communication manufacturing will continue to expand and optimize.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595