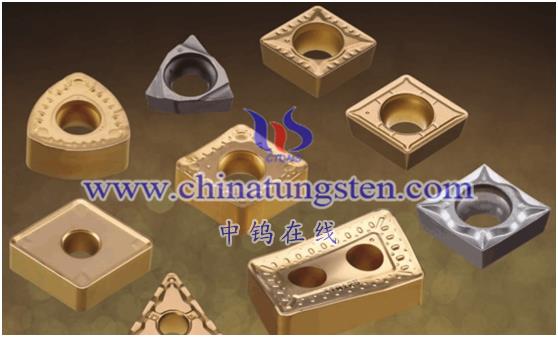

Carbide insert is a kind of insert widely used in various processing fields. Its main application areas include:

- Mechanical processing: In the field of mechanical processing, carbide inserts are widely used in the processing processes of lathes, milling machines, drilling machines, boring machines and other equipment, such as turning, milling, drilling, boring and other processing processes. In these processing processes, carbide inserts can improve processing efficiency and processing quality, while reducing production costs.

- Cutting field: In the cutting field, carbide blades are widely used in stone cutting, metal cutting, plastic cutting and other processing processes. These blades feature high wear resistance, long life and high efficiency, enabling high-precision cutting and machining.

- Aerospace: In the aerospace field, carbide blades are widely used in the processing of aircraft engines, wheels, fuselages and other parts. Because aerospace materials typically have high hardness, strength, and heat resistance, they require the use of carbide blades for processing.

- Medical devices: In the field of medical devices, carbide blades are usually used to make medical devices such as scalpels, scissors, and needles. The manufacturing of these instruments requires extremely high precision, requiring the use of high-precision, high-hardness cutting tools. Carbide blades not only have high hardness and precision, but are also harmless to the human body, ensuring the safety and reliability of the surgical process.

In general, carbide inserts, as a high-performance cutting tool, play an important role in mechanical processing, aerospace, medical equipment and other fields.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595