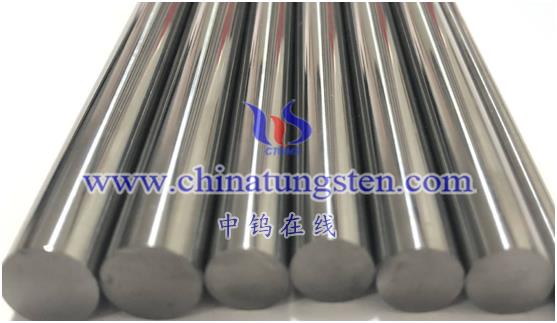

The cemented carbide round bar extrusion process is a process for manufacturing cemented carbide round bars. This process applies powder metallurgy technology to the manufacture of round bars, mainly through steps such as pressing and sintering to manufacture cemented carbide round bars.

Specifically, the extrusion molding process mainly includes the following steps:

- Mixed powder preparation: Mix the raw material powders of cemented carbide (such as tungsten carbide, titanium carbide, silicon carbide, etc.) according to a certain proportion, and add an appropriate amount of additives to make a mixed powder.

- Pressing: Fill the mixed powder into the mold, and then pressurize the mold to deform and press it into the shape of the carbide rod.

- Sintering: The pressed carbide rods are sintered at high temperature to make the alloy composition more stable and to increase the hardness and strength.

- Processing: Process the sintered carbide rods, such as turning, drilling, etc., to obtain the required shape and size.

The extrusion molding process has the advantages of high production efficiency, high material utilization, and good product performance consistency, so it has been widely used in the field of cemented carbide bar manufacturing.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595