The cemented carbide round bar extrusion forming process is suitable for making drill bits, cutting tools and other tools, and has the characteristics of high strength, high hardness and good wear resistance. Its application scenarios specifically include:

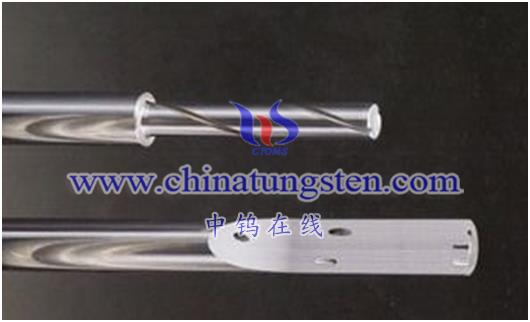

- Making drill bits: The carbide round rod extrusion molding process can produce drill bits of various specifications, such as straight shank drill bits, tapered shank drill bits, etc., which are suitable for drilling of various materials.

- Making cutting tools: The carbide round bar extrusion molding process can produce cutting tools of various shapes, such as turning cutters, milling cutters, gear cutters, etc., which are suitable for cutting of various metal and non-metallic materials.

- Production of wear-resistant parts: The carbide round bar extrusion molding process can produce various wear-resistant parts, such as sealing rings, bearing sleeves, etc., which are suitable for sealing and lubrication systems of various mechanical equipment.

- Production of structural parts: The carbide round bar extrusion molding process can produce various structural parts, such as guide rails, sliders, support frames, etc., which are suitable for the basic structures and moving parts of various mechanical equipment.

In short, the cemented carbide round bar extrusion forming process, as an advanced material processing technology, has been widely used in machinery manufacturing, aerospace, automobile manufacturing, mining and metallurgy and other fields.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595