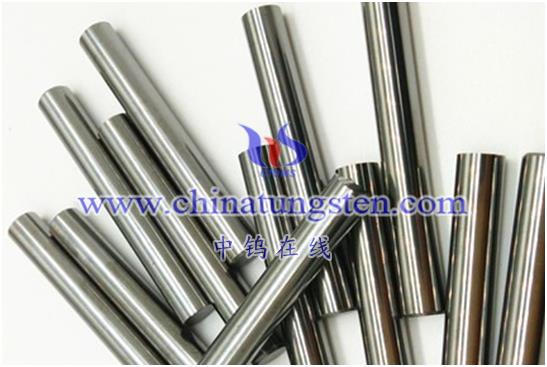

High-hardness and wear-resistant tungsten steel round rod with holes is an alloy bar made of cemented carbide tungsten steel (WC) as the main raw material, plus cobalt powder, tungsten carbide, etc., which is pressed and sintered by the powder metallurgy process. It has high hardness, high strength, high wear resistance, corrosion resistance and other properties. At the same time, the bar has holes, hence its name.

The manufacture of this high-hardness and wear-resistant tungsten steel holed round rod requires multiple complex process steps and strict process control, including mixed powder preparation, pressing, sintering and processing. During the manufacturing process, various process parameters need to be strictly controlled to ensure product quality stability and reliability.

High-hardness and wear-resistant tungsten steel holed round rods can be used in the manufacturing of various high-strength, high-wear-resistant parts or tools, such as aerospace, petrochemical, automobile manufacturing and other fields. In these fields, it can be used to manufacture various high-precision and high-demand parts or tools, such as turbine blades of aerospace engines, high-speed train hubs, pump shafts, etc.

In short, high-hardness and wear-resistant tungsten steel holed round rods are an alloy that uses carbide tungsten steel as the main raw material and is manufactured through powder metallurgy technology with high hardness, high strength, high wear resistance, corrosion resistance and other characteristics. Bar stock. It can be widely used in the manufacturing of various high-strength, high-wear-resistant parts or tools, and has unique structural and mechanical properties.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595