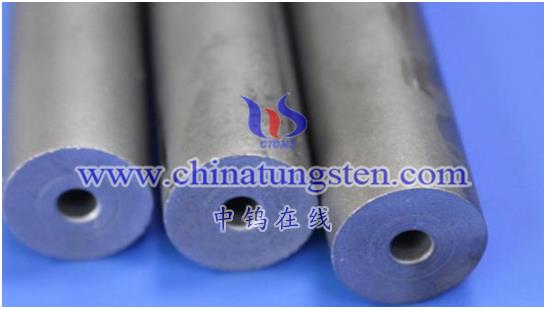

High-hardness and wear-resistant tungsten steel holed round bars can be used to manufacture high-speed cutting tools, molds, drill bits, cutting tools, etc. The main purpose is to manufacture high-speed cutting tools, molds, drill bits, cutting tools, etc. that require high cutting performance and life. Because tungsten steel round bars have high hardness, high wear resistance and high temperature stability, they can maintain stable cutting performance and service life in harsh environments such as high-speed cutting and high-temperature processing. In mold manufacturing, tungsten steel round rods can make high-precision, high-wear-resistant molds, improving the service life and processing accuracy of the molds. In the manufacturing of drill bits and cutting tools, tungsten steel round rods can make cutting tools with high hardness and high wear resistance, improving cutting efficiency and processing quality. In addition, tungsten steel round bars can also be used to manufacture high-temperature parts, nuclear reactor materials, electronic devices, etc. In high-temperature environments, tungsten steel round bars can maintain stable mechanical properties and chemical stability, so they can be used to manufacture high-temperature components. Parts, such as aircraft engines, rocket engines, nuclear reactors, etc. In different fields of use, the models of tungsten steel round rods selected will also be different. When processing materials with a hardness of HRC45, YL10.2 and YU12 tungsten steel round bars are usually used, while when processing 55-degree materials, MT06U and YU06 tungsten steel round bars are considered. Of course, you can also choose MT12S tungsten steel round rods with completely imported raw materials, which is a sign of high-end products. In short, high-hardness and wear-resistant tungsten steel holed round rods have a wide range of applications and are mainly used for manufacturing cutting tools, molds, drill bits and cutting tools.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595