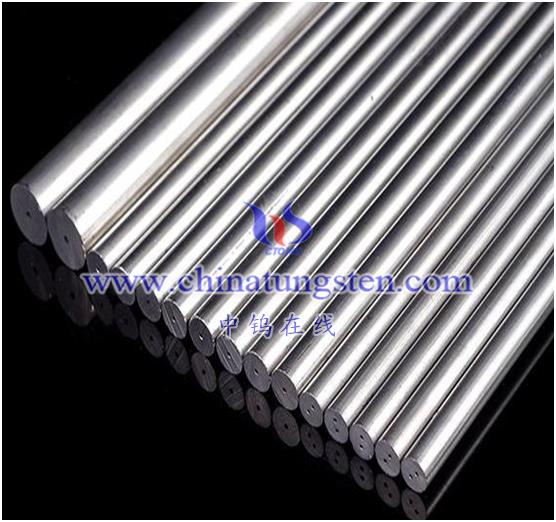

Tungsten carbide round rod is a super-hard material with extremely high hardness and wear resistance, so it is widely used in manufacturing high-precision, high-wear resistance, and high-performance mechanical parts and tools. Here are some common application scenarios:

- Cutting tool manufacturing: Due to the extremely high hardness and wear resistance of tungsten carbide, the cutting tools manufactured can cut workpiece materials of various hardnesses, and their service life is far longer than that of cutting tools made of other ordinary materials. Therefore, tungsten carbide round rods are widely used in manufacturing various cutting tools, such as twist drills, solid carbide blades, cutting tools, etc.

- Abrasive manufacturing: Tungsten carbide round rod is a material with excellent wear resistance and is widely used in the manufacture of grinding wheels and other abrasives. It has the highest hardness and the best wear resistance and can be used for grinding different materials such as metal, ceramics, glass, concrete, carbide, natural stone, and artificial stone.

- Manufacturing of high-temperature resistant components: Tungsten carbide has excellent thermal and chemical stability, so it is widely used in the manufacture of high-temperature resistant components and high-temperature stoves. For example, tungsten carbide resistor is one of the more common high-temperature resistant components and can work stably in environments with high temperature, vibration and chemical corrosion. In addition, tungsten carbide’s high wear resistance and low thermal expansion coefficient also make it commonly used to manufacture high-temperature flaps and thermocouples.

- Electronic device manufacturing: Tungsten carbide’s conductive properties and high thermal stability make it widely used in electronic device manufacturing. For example, in the manufacturing of energy switches, earthquake detectors, heat-resistant parts of high-frequency power tubes and flash lamp projectors, semiconductor materials, magnetic materials, etc.

In addition, tungsten carbide round rods can also be used to make small tools and equipment such as micro drills, as its high hardness and wear resistance provide better cutting and drilling performance. In general, tungsten carbide round rods play an important role in manufacturing high-precision, high-wear-resistant, and high-performance tools and equipment, and can be widely used in machinery manufacturing, petrochemical industry, automobile manufacturing, ceramics, glass and other fields.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595