Tungsten carbide round rods play a role in improving the hardness and wear resistance of cutting tools in tool manufacturing.

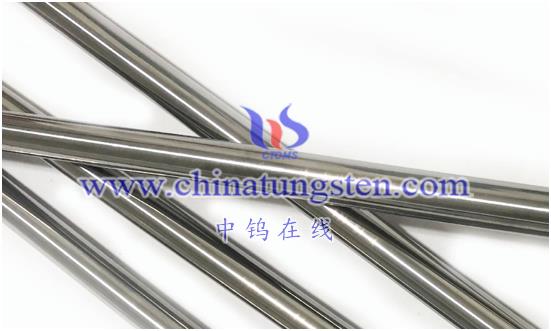

Tungsten carbide round rod is a compound composed of tungsten and carbon. It has high hardness and high wear resistance and can be used to manufacture various cutting tools, such as turning tools, milling cutters, drill bits, etc. Compared with traditional tool manufacturing materials, tungsten carbide round rods have higher hardness and wear resistance, which can significantly increase the cutting speed and efficiency of tools while maintaining the accuracy and surface quality of machined parts.

In some special application fields, such as high-speed cutting and cemented carbide processing, tungsten carbide round rods can also be used as the main manufacturing material of cutting tools, with better wear resistance and chipping resistance. In addition, tungsten carbide round rods also have good bending strength and toughness, which can improve the durability and service life of the tool.

In short, tungsten carbide round rods mainly play the role of improving the hardness and wear resistance of cutting tools in tool manufacturing. At the same time, they have good bending strength and toughness, which can significantly improve the performance and service life of cutting tools.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595