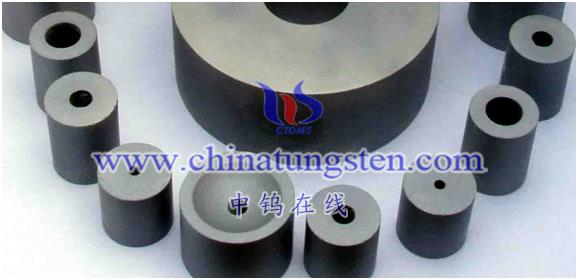

Wear-resistant cemented carbide small cylinder refers to a cylindrical blank made of wear-resistant cemented carbide material. It has the characteristics of high hardness, high wear resistance, high temperature resistance and good chemical stability, and can be widely used in various In the manufacturing of mechanical parts, such as wear-resistant bearings, wear-resistant gears, wear-resistant plungers, etc.

The manufacture of wear-resistant carbide small cylinders requires a series of complex process steps, including alloy ingredients, pressed blanks, high-temperature sintering, cooling treatment and surface treatment. During the manufacturing process, various process parameters need to be strictly controlled, such as sintering temperature, sintering time, cooling rate, etc., to ensure the compactness of the billet and the stability of the performance.

The main application field of wear-resistant cemented carbide small cylinders is the manufacturing of wear-resistant parts in heavy machinery and equipment, such as mining machinery, cement machinery, petrochemical machinery, etc. Because wear-resistant cemented carbide has high hardness, wear resistance and high temperature resistance, it is widely used in the manufacturing of key parts in these fields, which can significantly improve the reliability and service life of equipment.

In short, wear-resistant carbide small cylinders are an important wear-resistant material. The manufacturing process requires multiple complex links and precise control of process parameters to ensure that its performance and quality meet requirements.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595