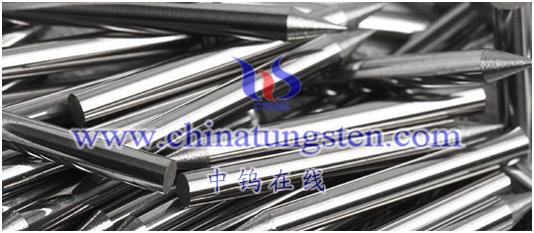

The manufacturing process of super-hard wear-resistant and high-precision tungsten carbide round rods mainly includes the following steps:

- Powder making: Mix the tungsten carbide powder with an appropriate amount of binder, lubricant, etc. evenly to make a slurry.

- Pressing: Pour the slurry into a steel mold and press it under a certain pressure to form a prefabricated part of a certain shape and size.

- Sintering: Put the pressed preforms into a furnace for high-temperature sintering, so that the tungsten carbide particles are sintered together to form a dense metallurgical combination.

- Finishing: rough and finish the sintered tungsten carbide round rod to achieve the required dimensional accuracy and surface roughness. Specific processing methods include cutting, grinding, polishing, etc.

- Inspection: Conduct dimensional inspection, hardness inspection, metallographic structure observation, etc. on the processed tungsten carbide round rods to ensure that they meet relevant standards.

During the manufacturing process, it is necessary to strictly control the process parameters and raw material quality of each step, and select appropriate production equipment and strict quality management systems to ensure that the manufactured tungsten carbide round rods have excellent performance and reliability. Specific process technologies and parameters may vary slightly due to different manufacturers and actual production conditions.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595