The specific steps for shield machines to use carbide shield cutters when constructing tunnels are as follows:

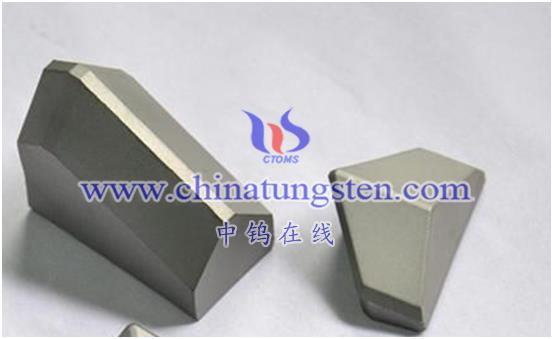

- Install carbide shield cutters on the cutterhead, and determine the type and quantity of cutters according to geological conditions and tunnel design requirements.

- Start the shield machine and start excavation work.

- The carbide shield cutter cuts and excavates the soil and rocks during the excavation process. At the same time, the shield machine’s propulsion system and support system will be adjusted accordingly according to the changes in the stratum to maintain the stable excavation of the shield machine.

- The cut earth and stone are transported to the outside of the tunnel through the conveyor belt of the shield machine to complete the tunnel excavation operation.

- During the excavation process, it is necessary to strengthen the monitoring and maintenance of the shield machine’s cutting tools, and promptly replace worn or damaged cutting tools to ensure the quality and progress of tunnel construction.

It should be noted that the carbide shield cutter is one of the most critical components in the shield machine, and its cutting ability and stability directly affect the construction quality and efficiency of the tunnel. Therefore, when selecting and using carbide shield cutters, factors such as geological conditions, cutter type, and material quality need to be fully considered to ensure that they can adapt to the requirements of tunnel construction.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595