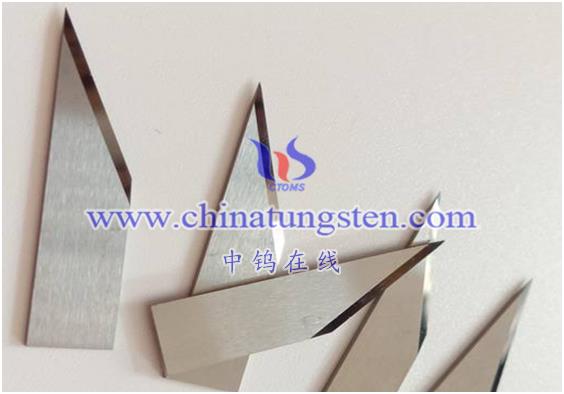

Medical devices made of cemented carbide have many advantages, including the following:

- High strength and wear resistance: Carbide has high strength and wear resistance, which can ensure good durability and stability of medical devices during use. For example, surgical blades made of carbide can withstand long-term high-intensity use, and the cutting effect and service life have been significantly improved.

- Good biocompatibility: Carbide has good biocompatibility and will not cause an overreaction of the human immune system, so it will not have a negative impact on the patient’s health. At the same time, this material will not affect the signal strength of medical imaging equipment, making medical diagnosis and treatment easier.

- Strong corrosion resistance: When carbide is used in medical equipment, it will not react with medical water, chemicals and other substances, so it can maintain the stability and safety of medical equipment.

- High processing accuracy: The processing accuracy of cemented carbide is very high, which can meet the strict requirements for accuracy and surface quality in medical device manufacturing.

- High safety: Carbide does not release harmful substances at high temperatures, so using this material to make medical devices can ensure patient safety.

In short, as a high-performance material, cemented carbide plays an irreplaceable role in the manufacturing of medical devices and is widely used in a variety of medical equipment and instruments. These application cases demonstrate the important position and role of cemented carbide in medical device manufacturing.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595