Commonly used cemented carbides are divided into three categories according to their composition and performance characteristics: tungsten-cobalt, tungsten-titanium-cobalt, and tungsten-titanium-tantalum (niobium). The most widely used in production are tungsten-cobalt and tungsten-titanium-cobalt cemented carbide.

(1) Tungsten-cobalt cemented carbide

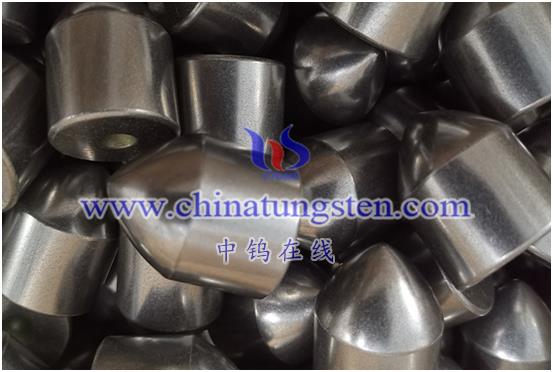

The main components are tungsten carbide (WC) and cobalt. The brand name is represented by the code YG (prefixed by the Chinese pinyin of “hard” and “cobalt”), followed by the percentage value of the cobalt content. For example, YG6 represents a tungsten-cobalt cemented carbide with a cobalt content of 6% and a tungsten carbide content of 94%.

(2) Tungsten titanium cobalt carbide

The main components are tungsten carbide (WC), titanium carbide (TiC) and cobalt. The brand name is represented by the code YT (prefixed by the Chinese pinyin of “hard” and “titanium”), followed by the percentage value of titanium carbide content. For example, YT15 represents a tungsten-titanium-cobalt carbide with a titanium carbide content of 15%.

(3) Tungsten titanium tantalum (niobium) carbide

This type of cemented carbide is also called universal cemented carbide or universal cemented carbide. Its main components are tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC) or niobium carbide (NbC) and cobalt. The brand name is represented by the code YW (prefixed by the Chinese pinyin of “hard” and “wan”) followed by an ordinal number.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595