Different types of blade materials differ in composition, performance and application.

- High-speed steel (HSS) is one of the most common blade materials. It has the advantages of high hardness, high strength, and good wear resistance. It is suitable for processing iron, steel and other metal materials. The production process of high-speed steel blades is relatively simple and the cost is low. It is suitable for occasions where the surface requirements are not high and the dosage is large. But its disadvantage is that it has a short lifespan because its hardness is not high and it is easy to wear.

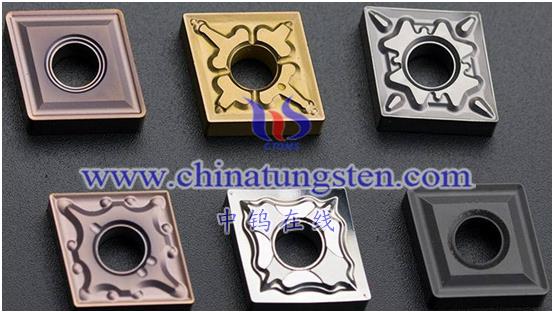

- The main components of cemented carbide blades are tungsten, cobalt, titanium, chromium, molybdenum and other metal powders and their acid compounds. They have the advantages of high hardness, good wear resistance, bending resistance and good wear resistance. Suitable for processing cast iron, non-ferrous metals and hot-processed steel with high hardness. However, the cost of cemented carbide blades is higher and the processing is more difficult. In situations where high surface requirements are required, problems such as edge cracking may occur.

- Ceramic blades have the characteristics of high hardness, wear resistance and high temperature stability. Suitable for processing difficult-to-machine materials such as high-temperature alloy materials. However, the cost of ceramic blades is relatively high, and the requirements for production and grinding are also relatively high.

- Polycrystalline cubic boron nitride blades have extremely high hardness and thermal stability, and can handle high-speed processing of steel and cast iron materials without coating. However, polycrystalline cubic boron nitride blades are more expensive and difficult to process.

Generally speaking, blades made of different materials have different advantages and disadvantages, and the selection should be comprehensively weighed based on factors such as processing materials, surface roughness, and service life.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595