There is a wide range of carbide types and end applications, here are some common types and uses:

- Tungsten-cobalt cemented carbide (YG): The main components are tungsten carbide (WC) and binder cobalt (Co). This alloy has low hardness, but has high toughness, good thermal conductivity, low cutting temperature, good grindability and sharp cutting edge. In cutting processing, the commonly used grades of YG alloys include YG3X, YG6X, YG6, YG8, etc., which are often used to process metal materials such as steel and cast steel.

- Tungsten titanium cobalt carbide (YT): The main components are tungsten carbide, titanium carbide (TiC) and cobalt. This alloy has high hardness but low bending and αk. As the TiC content increases, its thermal conductivity, sharpening properties, and weldability will decrease. However, it has better heat resistance. In cutting processing, the commonly used grades of YT alloys are YT5, YT14, YT15, YT30, etc., which are often used to process stainless steel, cast iron and other metal materials.

- Tungsten titanium tantalum (niobium) cobalt carbide (YW): the main components are tungsten carbide, titanium carbide, tantalum carbide or niobium carbide and cobalt. This alloy, known as universal carbide or universal carbide, features grain refinement, improved bending, αk, bend-1 and high-temperature properties while maintaining high hardness. Commonly used grades include YW1, YW2, etc., which are often used for processing cast iron and non-metallic materials.

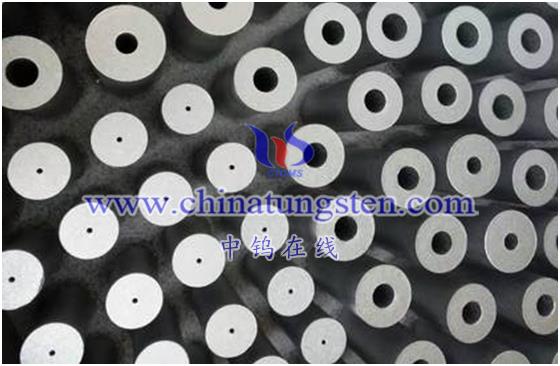

- Coated cemented carbide: usually refers to the coating of several microns of TiC, TiN, Ti(C,N), and Al2O3 on a tough tungsten carbide-based cemented carbide substrate through chemical vapor deposition or physical coating. Made of other coating hard compounds. These coatings can improve the wear resistance, corrosion resistance and oxidation resistance of the tool, extending the service life of the tool.

In addition, there are also cemented carbide for specific purposes, such as for the manufacture of cutting tools, wear-resistant parts, structural materials, etc. In these fields, cemented carbide is widely used due to its high hardness, high strength, corrosion resistance, high temperature resistance and other properties.

It should be noted that the types and end applications of cemented carbide will continue to change with the continuous development of technology and changes in market demand. New carbide alloys are constantly emerging to meet higher performance requirements and a wider range of applications.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595