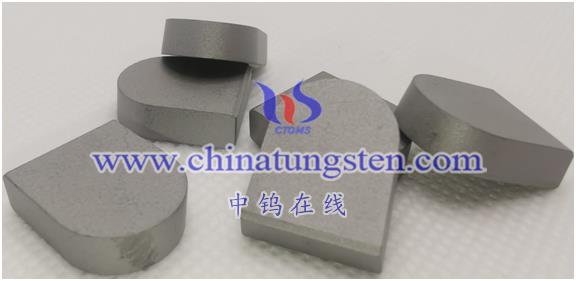

Tungsten-cobalt alloy has a wide range of applications in terms of wear resistance. Here are some specific examples:

- Cutting tool manufacturing: The high hardness, wear resistance and bending and fracture strength of tungsten-cobalt alloy make it an ideal material for manufacturing cutting tools. These tools include drills, milling cutters, turning tools and blades, etc., which can be used to process materials such as steel, cast iron, stainless steel, copper, copper alloys, especially high-hardness materials such as carbide, quartz glass, etc.

- Manufacturing of wear-resistant parts: Tungsten-cobalt alloy can be used to manufacture various wear-resistant parts, such as gears, bearings, piston rings, seals, etc. These parts need to maintain their shape and mechanical properties in harsh working environments and not be easily deformed and damaged.

- Mining equipment manufacturing: In coal mining equipment, tungsten-cobalt alloy can be used to manufacture wear-resistant parts, such as shearer cutting heads and cemented carbide picks. These parts need to withstand severe impact and wear, and the use of tungsten-cobalt alloy can effectively reduce the frequency of repairs and replacements.

- Metallurgical equipment manufacturing: In metallurgical equipment, tungsten-cobalt alloy can be used to manufacture smelting furnace linings, electric furnace containers, etc. These devices need to withstand high temperatures and corrosion, and using tungsten-cobalt alloy can improve the durability and thermal efficiency of the equipment.

In short, tungsten-cobalt alloy has a wide range of applications in terms of wear resistance, covering engineering machinery, coal mining equipment, metallurgical equipment and other fields. Its high hardness and strength, as well as good wear resistance, make it widely used in these fields.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595