There are obvious differences between high-speed steel and cemented carbide in terms of composition, performance and application scenarios.

- Composition: High-speed steel is an alloy with tungsten, cobalt, chromium and vanadium as the main component, while cemented carbide is mainly composed of tungsten-cobalt compounds.

- Performance: High-speed steel has good wear resistance and high physical and mechanical properties such as bending strength, impact strength and hardness, but its thermal stability is poor. Cemented carbide has high hardness and strength, and its hardness is also very high after heat treatment, but its toughness is poor and cannot be processed.

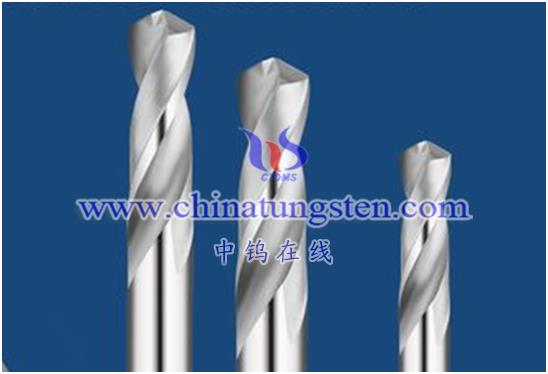

- Application scenarios: High-speed steel is suitable for manufacturing high-speed cutting tools, cutting tools and measuring tools, while cemented carbide is suitable for manufacturing high-performance wear-resistant tools, such as carbide cutting tools.

In general, high-speed steel and cemented carbide have obvious differences in composition, performance and application scenarios.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595