The measurement methods of strength and strength of different types of metal materials are different. Common methods of measuring the strength and strength of metal materials are as follows:

Steel material:

- Tensile test: During the stretching process of the tensile specimen, the elastic modulus, yield strength, tensile strength, elongation and other indicators of the material can be measured.

- Impact test: During the impact process of the impact sample, the impact toughness of the material can be measured.

- Hardness test: The hardness of materials can be measured through a hardness tester. Commonly used hardness testing methods include Brinell hardness, Rockwell hardness and Vickers hardness.

- Bending test: During the bending process of the bending specimen, the bending strength and bending modulus of the material can be measured.

Aluminum alloy material:

- Tensile test: During the stretching process of the tensile specimen, the elastic modulus, yield strength, tensile strength, elongation and other indicators of the material can be measured.

- Hardness test: The hardness of materials can be measured through a hardness tester. Commonly used hardness testing methods include Brinell hardness, Rockwell hardness and Vickers hardness.

- Bending test: During the bending process of the bending specimen, the bending strength and bending modulus of the material can be measured.

Copper alloy material:

- Tensile test: During the stretching process of the tensile specimen, the elastic modulus, yield strength, tensile strength, elongation and other indicators of the material can be measured.

- Hardness test: The hardness of materials can be measured through a hardness tester. Commonly used hardness testing methods include Brinell hardness, Rockwell hardness and Vickers hardness.

- Bending test: During the bending process of the bending specimen, the bending strength and bending modulus of the material can be measured.

Titanium alloy material:

- Tensile test: During the stretching process of the tensile specimen, the elastic modulus, yield strength, tensile strength, elongation and other indicators of the material can be measured.

- Hardness test: The hardness of materials can be measured through a hardness tester. Commonly used hardness testing methods include Brinell hardness, Rockwell hardness and Vickers hardness.

- Bending test: During the bending process of the bending specimen, the bending strength and bending modulus of the material can be measured.

- Fatigue test: Fatigue test can measure the fatigue limit and fatigue life of materials.

Magnesium alloy material:

- Tensile test: During the stretching process of the tensile specimen, the elastic modulus, yield strength, tensile strength, elongation and other indicators of the material can be measured.

- Hardness test: The hardness of materials can be measured through a hardness tester. Commonly used hardness testing methods include Brinell hardness, Rockwell hardness and Vickers hardness.

- Bending test: During the bending process of the bending specimen, the bending strength and bending modulus of the material can be measured.

- Impact test: During the impact process of the impact sample, the impact toughness of the material can be measured.

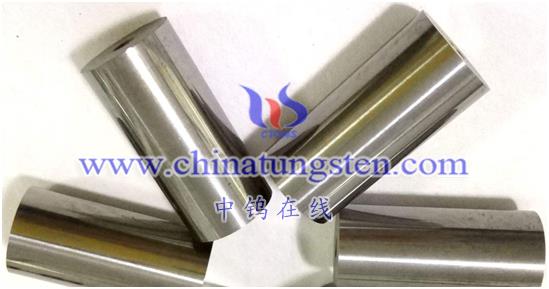

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595