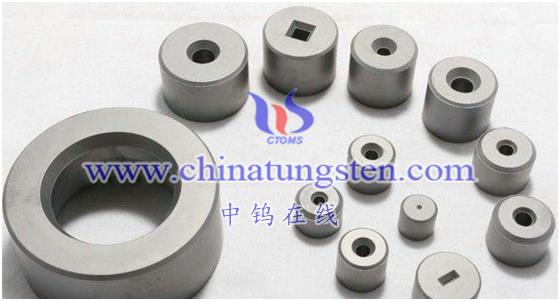

The manufacturing process of cemented carbide has a significant impact on the shape and size of the product. Here are some of the main factors:

- Mixture quality: Mixture quality is one of the key factors affecting the dimensional accuracy of press molding. Mixture quality includes its particle size, distribution and mix stability. The particle size and distribution will affect the density of the filler and the accuracy of pressing, while the stability of the mixture will affect the compressibility of the filler during the pressing process and the density of the sintered product.

- Press molding process: The design and implementation of the press molding process have an important impact on the shape and size of the product. The charging method, pressurization method, pressing speed and temperature in the pressing process will all affect the density distribution, shrinkage and dimensional accuracy of the product.

- Mold accuracy: The accuracy of the mold is one of the key factors affecting the dimensional accuracy of pressed products. The fitting clearance of the mold, the roughness of the working surface and the structural stiffness will all affect the dimensional accuracy and quality of the pressed products.

- Press accuracy: Press accuracy has a great impact on the dimensional accuracy of pressed products. The guide accuracy, work surface accuracy, synchronization accuracy and loading accuracy of the press will all affect the dimensional accuracy and quality of pressed products.

In addition, shrinkage and deformation during the sintering process will also affect the final size and shape of the product. Therefore, in the manufacturing process of cemented carbide, it is necessary to comprehensively consider various factors and adopt appropriate manufacturing processes and pressing parameters to obtain high-quality, high-precision cemented carbide products.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595