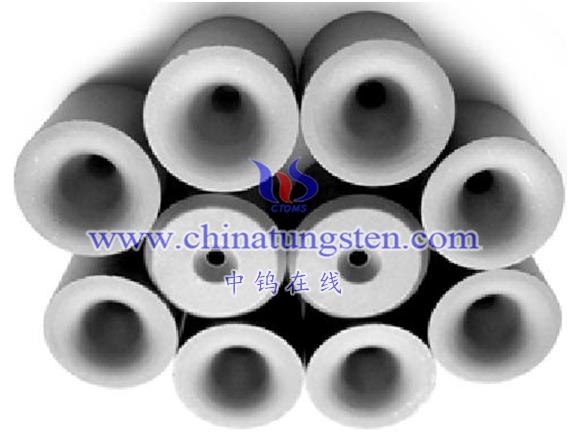

Carbide nozzles and cutting wheels have the following characteristics in application:

- Strong wear resistance: Because cemented carbide has high hardness and high wear resistance, it will not wear easily even if it is used for a long time in a harsh working environment.

- Strong heat resistance: Carbide has high thermal strength and can maintain good mechanical properties and heat resistance at high temperatures, so it can ensure good use results in high temperature environments.

- Good chemical stability: Carbide has strong corrosion resistance and is not easily corroded and oxidized, so it will not affect the use effect due to chemical reactions with surrounding substances.

- Good strength and toughness: Carbide has high strength, high toughness and high wear resistance, can withstand high impact and vibration, and is not prone to cracks and breakage.

- Improve production efficiency: Due to the excellent characteristics of the carbide nozzle and cutting wheel, the number of tool changes can be reduced and production efficiency can be improved.

- Reduce costs: Using carbide nozzles and cutting wheels can reduce the number of repairs and tool replacements and reduce production costs.

In summary, carbide nozzles and cutting wheels have excellent wear resistance, heat resistance, chemical stability, high strength and high toughness, etc. These characteristics make them have broad application prospects in industrial applications.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595