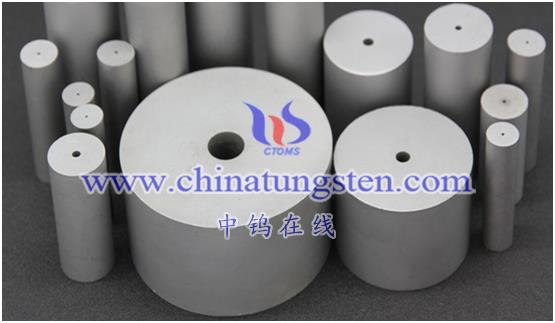

They are generally classified according to alloy composition, and the description of uses is relatively loose. Classification of tungsten carbide-based cemented carbide: including WC-Co, WC-TaC-Co, WC-TiC-Co, WC-TiC-TaC-Co, WC-Ti-TaC-NbC-Co and other alloys. These alloys are carbonized Tungsten is the main component. Titanium carbide-based or titanium carbonitride-based cemented carbide: a cemented carbide generally composed of TiC or Ti (C, N) as the basic component and Ni-Mo as the binder. There have been many new developments in this type of cemented carbide in recent years, such as multi-complex carbide solid solutions containing heavy metal elements such as Ta and other heavy metal elements participating in the development of high-performance TiW (C, N)-based cermets. Chromium carbide-based cemented carbide: a cemented carbide based on Cr3C2 and Ni or Ni-W as a binder. It is generally used for wear-resistant and corrosion-resistant parts. In recent years, it has also been used in many decorative parts. Such as watch chains, etc. Steel-bonded cemented carbide: a cemented carbide based on TiC or WC and steel as a binder. It is an alloy that can be machined and heat treated. It is between traditional cemented carbide and alloy steel. An engineering data between. Coated cemented carbide: generally refers to coating a tough tungsten carbide-based cemented carbide substrate with TiC, TiN, Ti (C, N), Al2O3 and the like with a thickness of several microns through chemical vapor deposition or physical coating methods. Produced from hard compounds.

The types of cemented carbide mainly include the following:

Tungsten-cobalt cemented carbide: the main components are tungsten carbide (WC) and binder cobalt (Co). Its brand name consists of “YG” (the first Chinese pinyin of “hard, cobalt”) and the percentage of average cobalt content. For example, YG8 means that the average WCo=8%, and the rest is tungsten carbide tungsten cobalt carbide. This type of alloy is mainly suitable for carbide cutting tools, molds and geological and mineral products.

Tungsten titanium cobalt cemented carbide: the main components are tungsten carbide, titanium carbide (TiC) and cobalt. Its brand consists of “YT” (the prefix of the Chinese pinyin of “hard and titanium”) and the average content of titanium carbide. For example, YT15 means average TiC=15%, and the rest is tungsten titanium cobalt cemented carbide with tungsten carbide and cobalt content.

Tungsten titanium tantalum (niobium) carbide: the main components are tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This type of cemented carbide is also called universal cemented carbide or universal cemented carbide. Its brand name consists of “YW” (prefixed by the Chinese pinyin of “hard” and “wan”) plus a serial number, such as YW1.

Tungsten ferroalloy: It is composed of tungsten, iron and other elements. It has high hardness, high density and wear resistance. It is commonly used in mining tools, metallurgy and other fields.

In general, there are many types of cemented carbide, each type has its own characteristics and application range.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595