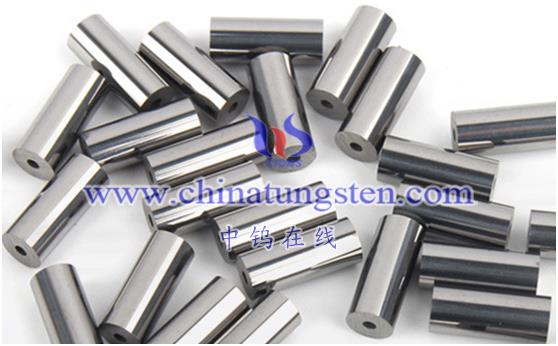

Wear-resistant non-standard tungsten steel cylinder is a high-hardness, high-strength alloy cylinder made of carbide tungsten steel (WC) as the main raw material, mixed with other precious metals and paste. It has excellent wear resistance and is suitable for manufacturing various wear-resistant parts and tools, such as knives, molds, mechanical parts, etc.

The manufacturing process of wear-resistant non-standard tungsten steel cylinders is similar to that of ordinary tungsten steel cylinders, but in order to improve its wear resistance, it is usually necessary to coat the surface with a layer of wear-resistant material. This layer of wear-resistant material can increase the hardness, strength and friction resistance of the wear-resistant non-standard tungsten steel cylinder, so that it can still maintain its shape and accuracy in harsh environments such as high temperature, high pressure or impact.

The characteristics of wear-resistant non-standard tungsten steel cylinders include high hardness, high strength, high wear resistance, high corrosion resistance, high fatigue resistance, etc. These characteristics make wear-resistant non-standard tungsten steel cylinders an ideal material for manufacturing various wear-resistant parts and tools, such as high-speed railway switches, carbide cutting tools, automobile brake pads, powder metallurgy molds, etc.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595