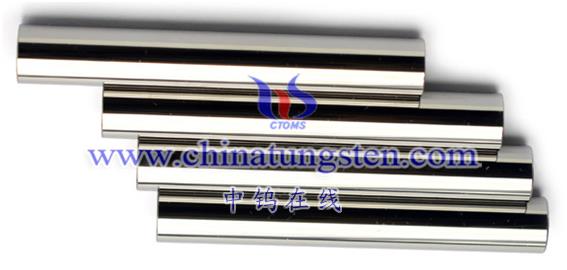

Knives and cutting tools made of tungsten carbide round rods have the characteristics of high hardness, high wear resistance, high corrosion resistance, high strength, etc., which can effectively improve the service life and cutting efficiency of cutting tools and cutting tools.

Specifically, the advantages of tungsten carbide cutting tools and cutting tools include:

- High hardness: Tungsten carbide is about ten times harder than steel, so it can effectively resist material wear and thermal expansion, improving the hardness and cutting performance of knives and cutting tools.

- High wear resistance: Due to the high hardness of tungsten carbide, it has good wear resistance, especially when processing high-hardness materials, it can maintain the cutting performance of the cutting edge and the tool life.

- High chemical stability: Tungsten carbide itself is very stable and does not react with most chemicals, so it is suitable for harsh working environments such as high temperature, high pressure, and corrosion.

- High cutting performance: Tungsten carbide cutting tools have good cutting performance, especially during high-speed cutting, and can well control the cutting force and heat generated, thereby achieving higher processing efficiency.

The price of tungsten carbide cutting tools and cutting tools is relatively high. For some special-purpose occasions, the cost and performance-price ratio need to be fully considered. At the same time, you also need to pay attention to the correct usage and maintenance during use to ensure its accuracy and service life.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595