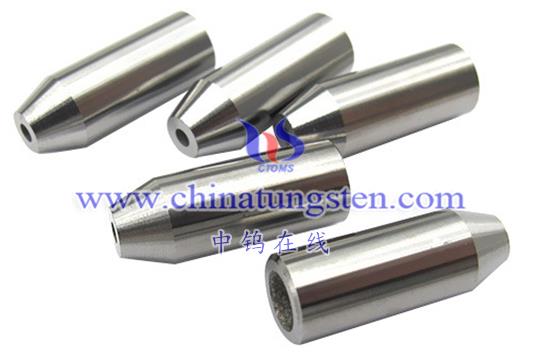

The carbide waterjet nozzle is made of precision machinery and carbide material (supercarbide) and is one of the key components in the high-pressure waterjet cutting system. It has the characteristics of high hardness, high wear resistance, and high corrosion resistance, and can withstand the impact and wear of the nozzle by high-pressure water flow while maintaining high-precision cutting effects.

During the manufacturing process, carbide waterjet nozzles undergo multiple processes, including material selection, batching, mixing, pressing, sintering, etc. These processes require strict quality control and technical requirements to ensure their dimensional accuracy. and surface quality.

Generally speaking, the hole diameter and shape of a carbide waterjet nozzle are also important features. Different shaped apertures and nozzle designs will directly affect the focusing effect and cutting accuracy of the water jet. In order to obtain maximum jet impact, high-pressure and ultra-high-pressure nozzles usually adopt cylindrical aperture designs. At the same time, there is a scientific curvature radius design at the two entrances to ensure the smooth passage of the thread.

Carbide waterjet nozzles have been widely used to cut various materials, such as metal, stone, glass, etc., with high cutting efficiency and precision, which effectively reduces cutting costs. At the same time, they can be used for a long time and are not easily damaged, reducing the frequency of tool replacement. .

The carbide waterjet nozzle is a precision component that needs to be manufactured and repaired by a professional manufacturer. At the same time, the operating procedures need to be strictly followed during use to ensure its stability and safety.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595