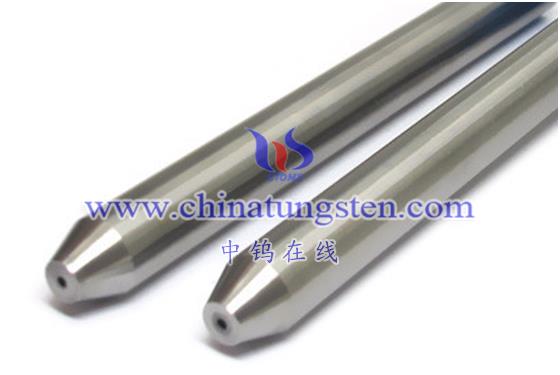

Carbide waterjet nozzles have the following characteristics:

- High hardness and high wear resistance: Carbide waterjet nozzles are made of carbide material. This material has high hardness and high wear resistance, which can maintain the shape and size of the nozzle stable for a long time, improving cutting equipment. reliability and service life.

- High corrosion resistance: The carbide waterjet nozzle has strong corrosion resistance and can resist the erosion of various chemical substances, effectively protecting other parts of the cutting equipment from corrosion.

- Good thermal conductivity: Carbide has excellent thermal conductivity, which is conducive to rapid heat conduction, reduces heat accumulation during the cutting process, and avoids overheating and cracking of the coating.

- High precision: The manufacturing process of carbide waterjet nozzles can achieve high precision, making the size and shape of the nozzle more accurate and improving the smoothness and density of the cutting edge.

- Low impact toughness: The impact toughness of the cemented carbide waterjet nozzle is low, brittle, and easily broken under the action of external force.

- Good chemical stability: Carbide waterjet nozzles have good chemical stability, are not easily oxidized and corroded, and can maintain long-term performance stability.

- High strength and high wear resistance: For different application fields and usage environments, carbide materials with corresponding characteristics should be selected, such as high strength, high wear resistance, high corrosion resistance, etc.

- Manufacturing process optimization: By optimizing the manufacturing process, the quality and performance of carbide waterjet nozzles can be improved. For example, advanced smelting and pouring technology is used to ensure the stability of the cemented carbide composition and structure; supersonic plasma sintering technology is used to improve the density and hardness of the nozzle.

In short, carbide waterjet nozzles have excellent properties such as high hardness, high wear resistance, high corrosion resistance, and good thermal conductivity, and are widely used in industrial production, aerospace, automobile manufacturing, electronic equipment and other fields. At the same time, based on actual application needs, the design, material selection and manufacturing process can be optimized to improve the performance and service life of the nozzle.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595