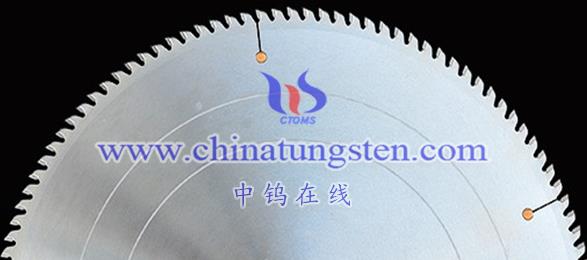

The tooth shapes of carbide sawtooth cutting blades mainly include the following:

- Flat teeth: This tooth shape is suitable for sawing ordinary wood. It has lower cost, slower cutting speed and is the easiest to grind. Flat teeth have a rougher kerf but less adhesion to the wood when cutting.

- Staggered bevel-ground teeth on the back tooth surface: This tooth shape is mainly used for the main saw blade of electronic cutting saws, and is suitable for sawing blockboards, plywood and artificial boards.

- One-way obliquely ground teeth on the rear tooth surface: This tooth shape is suitable for crushing knife saw blades and edge banding cutting saw blades.

- Left and right bevel grinding teeth: This tooth shape is suitable for sawing cross-sections of wood, aluminum alloys and plastic profiles.

- Left and right oblique grinding teeth and flat teeth: This tooth shape is suitable for vertical and horizontal sawing of wood and the main saw blade of veneer artificial panels.

- Trapezoidal teeth: This tooth shape is mainly used for sawing thin saw blades.

- Trapezoidal and flat teeth: This tooth shape combines the characteristics of trapezoidal teeth and flat teeth. The grinding is more complicated and is suitable for sawing various single and double veneer artificial boards and fireproof boards.

In general, different tooth shapes are suitable for different materials and cutting needs. When choosing a carbide saw-tooth cutting blade, comprehensive considerations need to be made based on the actual situation to select the most appropriate tooth shape and cutter.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595