The manufacturing process of tungsten steel saw blades mainly includes powder metallurgy and brazing.

Powder metallurgy is an important process for preparing tungsten steel materials. Its process includes powder preparation, pressing, sintering and subsequent processing. Tungsten steel materials prepared by powder metallurgy have the advantages of high density, high strength, high hardness, good wear resistance and corrosion resistance, and are suitable for manufacturing high-hardness cutting tools such as tungsten steel saw blades.

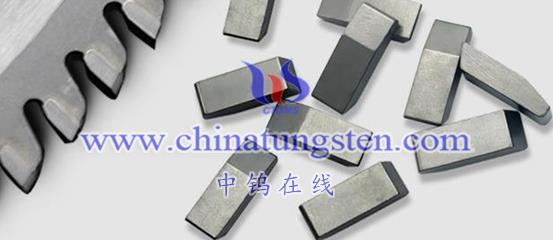

Brazing is a process that joins two different materials together through molten liquid metal. It is often used to make tungsten steel saw blades. The manufacturing process of brazed tungsten steel saw blades includes matrix smelting, matrix molding, cutter head smelting, cutter head welding and subsequent processing. Tungsten steel saw blades prepared by brazing have the advantages of high hardness, high strength, high wear resistance and high heat resistance, and can meet the cutting needs of various materials.

In addition to core manufacturing processes such as powder metallurgy and brazing, the manufacturing of tungsten steel saw blades also requires some auxiliary processes, such as heat treatment, grinding and assembly. These auxiliary processes can further optimize the performance and accuracy of the tungsten steel saw blade, ensuring better cutting effects and service life during use.

In short, the manufacturing process of tungsten steel saw blades has been carefully designed and optimized, including core processes such as powder metallurgy and brazing, as well as various auxiliary processes, to produce high hardness, high strength, high wear resistance and high heat resistance. of high quality cutting tools.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595