The design features of tungsten carbide saw blades and the differences between different types are mainly reflected in the following aspects:

- Raw materials and manufacturing process: Tungsten carbide saw blades are mainly made of tungsten carbide powder, cobalt powder and other materials, and are produced using powder metallurgy methods. Tungsten carbide saw blades from different brands and manufacturers may use different raw material formulas and manufacturing processes. These factors will affect the hardness and wear resistance of the product.

- Grain size and hardness: The grain size and hardness of the tungsten carbide saw blade are important factors affecting its cutting performance. Generally speaking, the finer the particle size and the higher the hardness, the better the wear resistance and cutting performance of the tungsten carbide saw blade. But at the same time, the increase in particle size and hardness will also lead to an increase in brittleness, thus affecting impact resistance and service life.

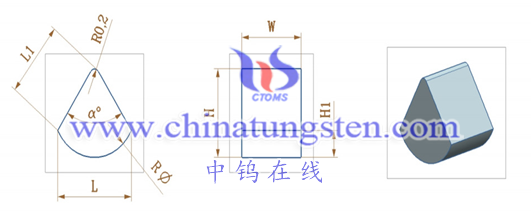

- Tooth shape and number of teeth: The tooth shape and number of teeth of the tungsten carbide saw blade are key factors affecting its cutting speed and cutting quality. Different brands and types of tungsten carbide saw blades may use different tooth shapes and tooth number designs, which will affect power output, heat generation, cutting accuracy, and material removal speed during the cutting process.

- Coating technology: Some high-end tungsten carbide saw blades will use coating technology, such as titanium nitride coating, to enhance their wear resistance and corrosion resistance and extend their service life. Coating technology can also improve the cutting performance of tungsten carbide blades, reduce heat generation and prevent sticking.

- Application fields: Tungsten carbide saw blades are mainly used for cutting high-hardness, high-wear-resistant materials such as carbide, ceramics, quartz, and glass. Different types and brands of tungsten carbide saw blades may be suitable for different application areas and need to be selected according to the specific use environment and requirements.

In short, the design characteristics of tungsten carbide saw blades and the differences between different types are mainly reflected in raw materials and manufacturing processes, particle size and hardness, tooth shape and number of teeth, coating technology, and application fields. When selecting tungsten carbide saw blades, comprehensive considerations need to be made based on specific usage requirements and application scenarios.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595