The high hardness of tungsten steel saw blades reduces wear and deformation mainly for the following reasons:

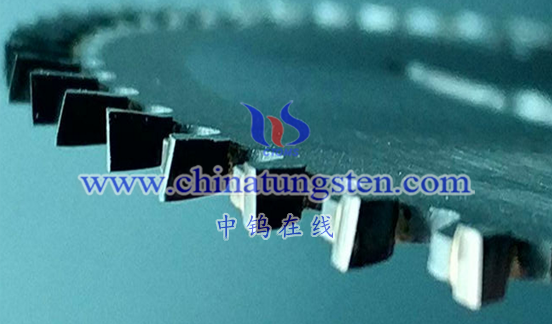

- Carbide material: Tungsten steel saw blades are made of carbide material, with a hardness of up to HRC60 or above. This high-hardness material can resist the cutting and wear of most metals, thereby reducing the wear and deformation of the saw blade.

- Precision grinding: After fine grinding, the surface smoothness and flatness of the tungsten steel saw blade are improved, which reduces the friction resistance during the cutting process, reduces heat generation and stress concentration, thereby reducing the wear and tear of the saw blade. Wear and deformation.

- Special binder: The tungsten steel saw blade uses a special binder to enhance its wear resistance and stability, making the saw blade less likely to vibrate, slip or deform during high-speed cutting, thereby reducing wear and deformation.

- Structural design: The tungsten steel saw blade adopts an optimized structural design, which can effectively improve its resistance to bending and twisting, and reduce deformation caused by stress concentration, thus improving the stability and service life of the saw blade.

- Strict quality control: Tungsten steel saw blades undergo strict quality control during the manufacturing process to ensure the accuracy and stability of each link, thereby ensuring the hardness and wear resistance of the final product and reducing wear and deformation.

In summary, the reasons why the high hardness of tungsten steel saw blades can reduce wear and deformation include carbide materials, precision grinding, special binders, optimized structures and strict quality control. These factors work together to make tungsten steel saw blades have excellent wear resistance and stability, and thus are widely used in cutting and processing of metal materials.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595