The die-casting mold is a tool for casting metal parts. It is mainly used to complete the die-casting process on a dedicated die-casting die forging machine. The structural design and manufacturing quality of die-casting molds play a vital role in ensuring the quality of castings, improving production efficiency and reducing production costs.

The design of the die-casting mold requires comprehensive consideration of a variety of factors, including the flow characteristics of the molten metal, cooling rate, filling characteristics, etc. At the same time, the design of the mold also needs to meet certain strength and wear resistance requirements to cope with high temperature, high pressure and high-speed impact of molten metal. Therefore, the selection of mold materials, heat treatment process and processing accuracy must be strictly controlled and optimized.

In actual production, the main failure modes of die-casting molds include thermal fatigue crack damage failure, fragmentation failure and corrosion failure. These failure modes are often related to various factors such as mold materials, structural design, manufacturing processes, and usage conditions. In order to avoid the occurrence of these failure modes, corresponding preventive measures need to be taken, such as optimizing mold design, selecting high-quality materials, and strengthening mold maintenance.

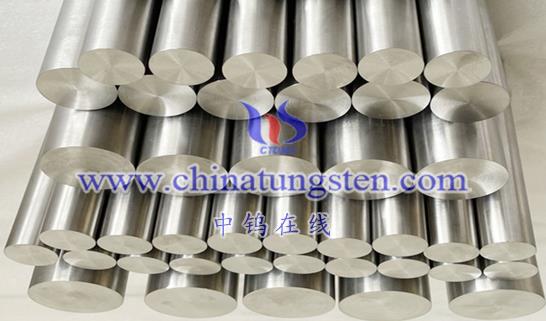

Tungsten-molybdenum-nickel-iron alloy is widely used in the field of die-casting molds, mainly due to its unique physical and chemical properties. The following are the specific applications of tungsten-molybdenum-nickel-iron alloy in the field of die-casting molds:

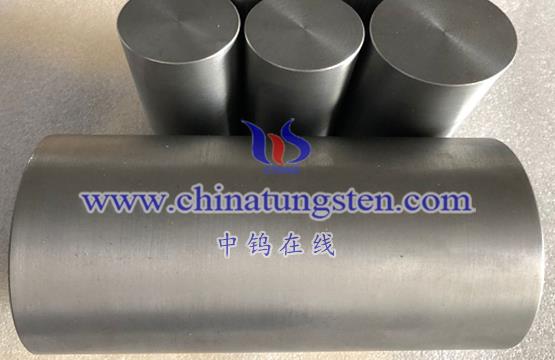

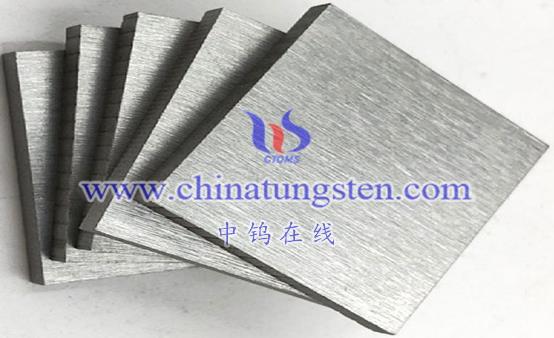

Mold material

Tungsten-molybdenum-nickel-iron alloy has become an ideal material for die-casting molds due to its high thermal conductivity, low thermal expansion coefficient and good red hardness. These properties enable the alloy to effectively resist high temperatures and pressures during high-pressure casting, thereby ensuring the dimensional accuracy and service life of the mold.

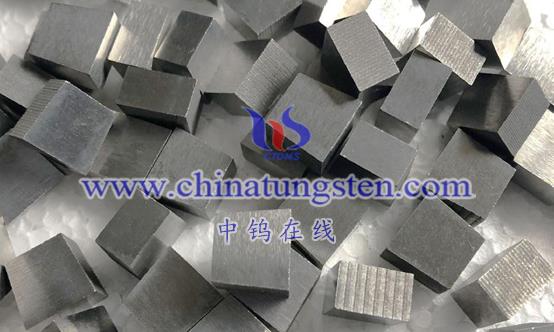

Mold core material

In complex die-casting molds, tungsten-molybdenum-nickel-iron alloy is also often used as the mold core material. Due to its high strength and high wear resistance, this alloy can withstand the high stress and wear experienced by the core, thereby improving the overall performance of the mold.

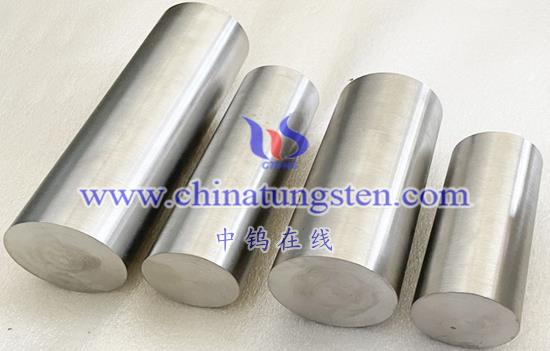

Mold slides and guide posts

Sliders and guide posts are important components in die-casting molds and need to withstand frequent sliding and friction. Tungsten-molybdenum-nickel-iron alloy is also widely used in these parts due to its high hardness and wear resistance, which can significantly improve the durability and stability of the mold.

Mold hot section

During the die-casting process, thermal nodes may form in certain parts of the mold, resulting in heat concentration and increased local thermal stress in the mold. Tungsten-molybdenum-nickel-iron alloy can effectively reduce the formation of hot spots due to its good thermal stability and thermal conductivity, thereby increasing the service life of the mold.

In addition to the above applications, tungsten-molybdenum-nickel-iron alloy can also be customized according to specific needs to meet the specific requirements of different die-casting molds. For example, the alloy’s composition and microstructure can be adjusted to optimize its thermal stability, wear resistance or mechanical properties to suit different die-casting conditions and working environments.

In short, tungsten-molybdenum-nickel-iron alloy has extensive and diverse applications in the field of die-casting molds. Its unique physical and chemical properties make it the preferred material in die-casting mold manufacturing.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595