Tungsten-molybdenum-nickel-iron alloy is widely used in the field of machining, mainly due to its unique physical and chemical properties, such as high hardness, good wear resistance, high thermal conductivity and low thermal expansion coefficient. The following are some of the main applications of tungsten-molybdenum-nickel-iron alloys in the field of machining:

cutting tools

Due to the high hardness and wear resistance of tungsten-molybdenum-nickel-iron alloy, it is often used to manufacture various cutting tools, such as turning tools, milling cutters, drill bits, etc. These tools can stay sharp for a longer period of time during the cutting process, improve cutting efficiency, and reduce the frequency of tool replacement.

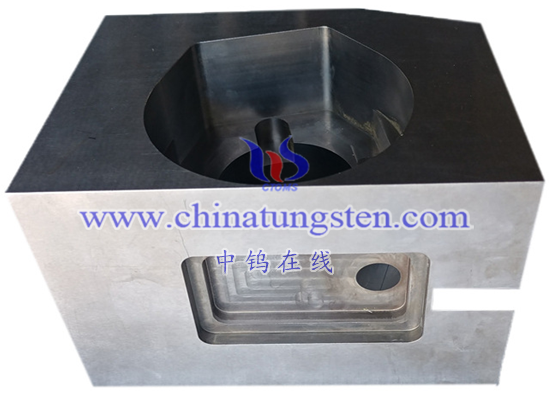

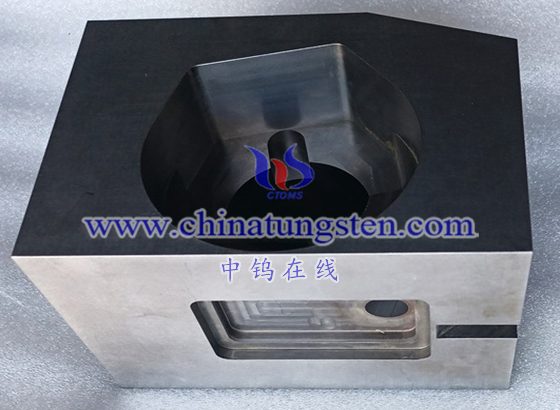

Mold making

Tungsten-molybdenum-nickel-iron alloy is also widely used in the field of mold manufacturing, especially in the manufacture of die-casting molds, forging molds and injection molds. Its high thermal conductivity and good wear resistance enable the mold to maintain good performance when withstanding high temperatures and pressures, extending the service life of the mold.

Mechanical Parts

The alloy can also be used to make mechanical parts that withstand high loads and temperatures, such as bearings, gears, pins, etc. Their high strength and good wear resistance allow these parts to maintain stable performance in harsh working environments.

surface coating

In addition, tungsten-molybdenum-nickel-iron alloy can also be used as a surface coating material to coat the surfaces of cutting tools, molds and other mechanical processing tools to improve their wear resistance, hardness and service life.

It should be noted that the specific application of tungsten-molybdenum-nickel-iron alloy is also affected by factors such as its composition, manufacturing process, and working environment. In practical applications, it is necessary to select the appropriate alloy composition and manufacturing process according to specific needs and conditions to obtain the best mechanical properties and processing effects.

In summary, tungsten-molybdenum-nickel-iron alloy has broad application prospects in the field of machining. Its unique physical and chemical properties make it an ideal choice for manufacturing efficient and durable cutting tools and mechanical parts.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595