The choice of bearing material has a crucial impact on the performance and life of the bearing. Common bearing materials mainly include metal materials, ceramic materials and plastic materials.

Metal materials are the most common bearing materials, among which carbon steel, stainless steel and alloy steel are widely used. Carbon steel has good strength and wear resistance and is suitable for bearings under general working conditions; stainless steel is especially suitable for bearings in humid or corrosive environments because of its excellent corrosion resistance; while alloy steel has higher strength And wear resistance, suitable for bearings under high load or high speed conditions. However, metal materials are prone to generate friction and heat when rotating at high speeds. Therefore, in some special working conditions, ceramic materials have become the choice to replace metal materials.

Ceramic materials mainly include alumina ceramics and silicon nitride ceramics. Alumina ceramics have good wear resistance and corrosion resistance and are suitable for bearings under high-speed rotation and high-temperature conditions; silicon nitride ceramics have higher hardness and wear resistance and are suitable for ultra-high-speed and ultra-high temperature conditions. lower bearing.

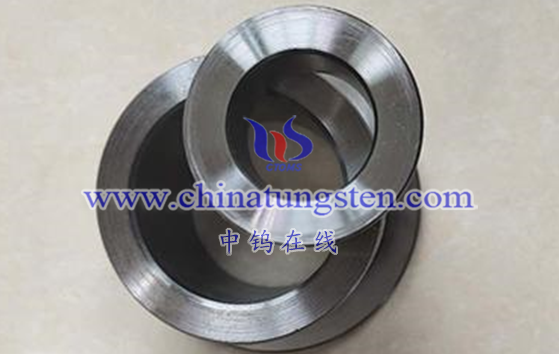

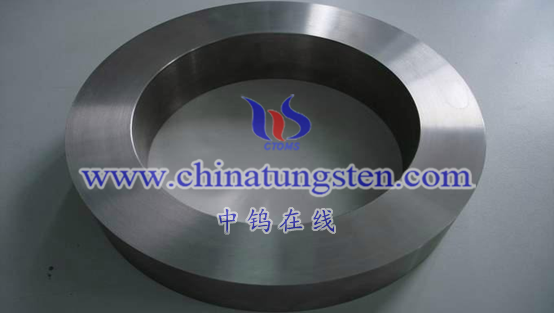

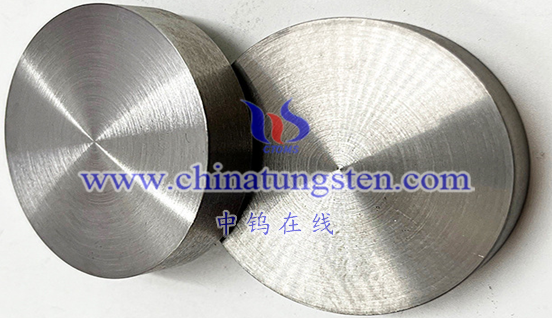

Plastic materials are also gradually used in bearings, such as nylon, polytetrafluoroethylene and polyimide. Plastic bearings have good self-lubricating and corrosion resistance, and are suitable for bearings under low load and low-speed working conditions, as well as bearings under special working conditions. In addition, there are some special bearing materials, such as bearing alloy (Babbitt alloy), bronze, lead copper and cast iron. Among these materials, tungsten-molybdenum-nickel-iron alloy performs well in certain specific application scenarios due to its unique physical and chemical properties. Tungsten-molybdenum-nickel-iron alloy bearing material has the following advantages:

High temperature stability

Tungsten-molybdenum-nickel-iron alloy can maintain good dimensional stability and mechanical properties in high temperature environments. The alloy’s high melting point allows it to operate at high temperatures without softening or deforming, ensuring bearing durability and reliability.

Excellent wear resistance

The alloy has excellent wear resistance and is able to maintain a long service life under conditions of friction and wear. This enables the tungsten-molybdenum-nickel-iron alloy bearing material to withstand long-term high-load operation, reducing the frequency of maintenance and replacement.

high strength

Tungsten-molybdenum-nickel-iron alloy has high strength and good load-bearing capacity, and can withstand the high load generated by the bearing during operation. This makes it suitable for applications that need to withstand heavy loads and shocks.

good thermal conductivity

The alloy has high thermal conductivity, allowing it to transfer and dissipate heat quickly. This helps reduce the thermal stress generated by the bearing during operation, reduces the risk of thermal failure, and maintains stable operation of the bearing.

good corrosion resistance

Tungsten-molybdenum-nickel-iron alloy has good corrosion resistance to many chemical media and can maintain stable performance in harsh working environments. This makes it have broad application prospects in chemical industry, marine and nuclear energy and other fields.

To sum up, tungsten-molybdenum-nickel-iron alloy bearing material has the advantages of high temperature stability, excellent wear resistance, high strength, good thermal conductivity and corrosion resistance. These advantages make it an ideal bearing material choice in fields such as aerospace, energy, automotive manufacturing and machine manufacturing.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595