Tungsten-molybdenum-nickel-iron alloy exhibits excellent performance and applicability when manufacturing hot-stamped valves. As an important component of automobile engines, hot stamped valves need to have high heat resistance, high strength and good wear resistance to cope with high temperature and high pressure working environments.

Tungsten-molybdenum-nickel-iron alloy has become an ideal material for manufacturing hot stamped valves due to its high melting point, high hardness, good thermal stability and corrosion resistance. At high temperatures, the alloy can maintain high strength and hardness, effectively resist thermal deformation and wear, and ensure stable operation of the valve in high-temperature and high-pressure working environments.

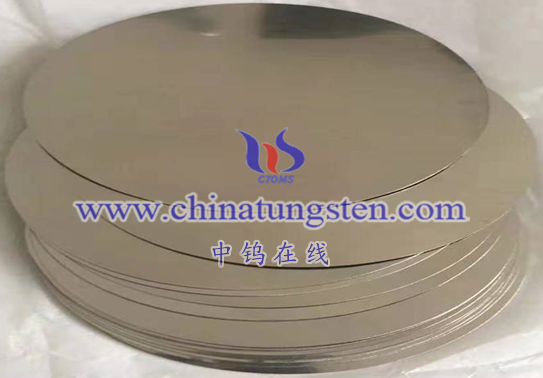

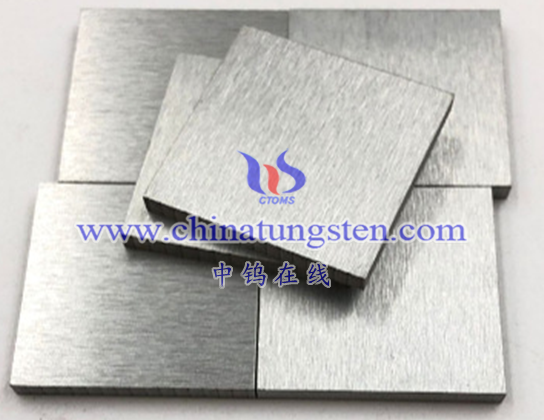

In addition, tungsten-molybdenum-nickel-iron alloy also has good processing properties and can be processed into complex-shaped valve components through hot stamping and other processes. This makes the alloy highly flexible and adaptable in the valve manufacturing process, and can meet the needs of valve manufacturing of different models and specifications.

Therefore, tungsten-molybdenum-nickel-iron alloy has broad application prospects in the field of hot stamping valve manufacturing. It can not only improve the performance and service life of the valve, but also reduce production costs, improve production efficiency, and contribute to the development of the automotive industry.

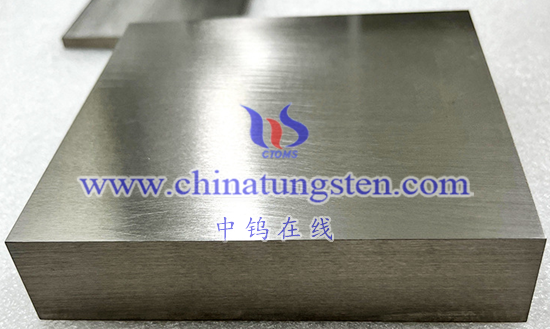

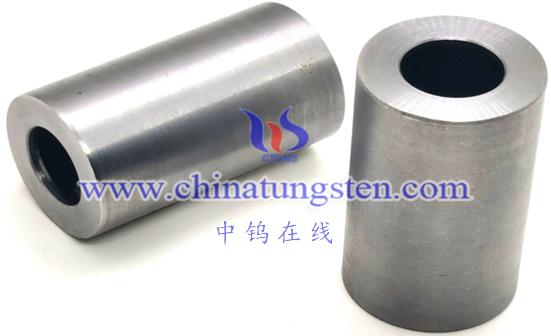

The application of tungsten-molybdenum-nickel-iron alloy in the field of hot stamping valves is mainly reflected in its use as anvil block material for valve stamping. This alloy has excellent thermal conductivity and high temperature properties, maintaining good red hardness even at 1100°C. Therefore, it can significantly increase the service life of the anvil block and ensure the stability and reliability of the valve during the hot stamping process.

Specifically, tungsten-molybdenum-nickel-iron alloy can be used to manufacture anvil blocks in valve stamping dies, which can withstand high-temperature and high-pressure working environments while having excellent wear resistance and thermal fatigue resistance. This allows the valve to maintain precise size and shape during the hot stamping process, improving production efficiency and product quality.

In short, tungsten-molybdenum-nickel-iron alloy has broad application prospects in the field of hot stamping valves due to its unique high-temperature properties and thermal conductivity, providing a reliable material solution for valve manufacturing.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595