The application of tungsten-molybdenum-nickel-iron alloy in the automotive industry is mainly reflected in the following aspects:

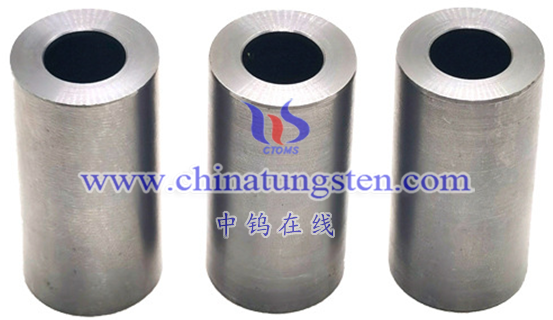

engine parts

Due to its high strength, high wear resistance and excellent high temperature stability, tungsten-molybdenum-nickel-iron alloy is widely used in key components of engines, such as valves, piston rings and bearings. These components need to withstand high temperatures, high pressures and high-speed operations, and the excellent properties of tungsten-molybdenum-nickel-iron alloys can meet these requirements and improve engine performance and reliability.

transmission parts

The transmission is an important part of the car, and its components such as gears and bearings also need to withstand high-speed operation and heavy loads. Tungsten-molybdenum-nickel-iron alloy is used to manufacture these components to improve the durability and stability of the transmission due to its high strength and good wear resistance.

In addition, because tungsten-molybdenum-nickel-iron alloy also has low expansion coefficient, high thermal conductivity and good red hardness, it is also widely used in the field of die-casting molds in the automotive industry, especially in the field of anvil blocks in the field of hot forging valves.

The above information is for reference only. With the advancement of technology and the continuous development of materials, the application of tungsten-molybdenum-nickel-iron alloy in the automotive industry may be increased or adjusted. Therefore, it is recommended to evaluate and select based on specific circumstances in actual applications.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595