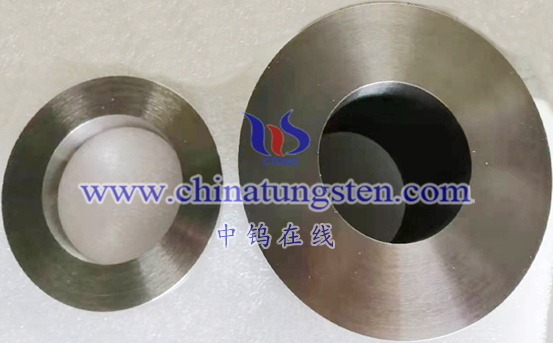

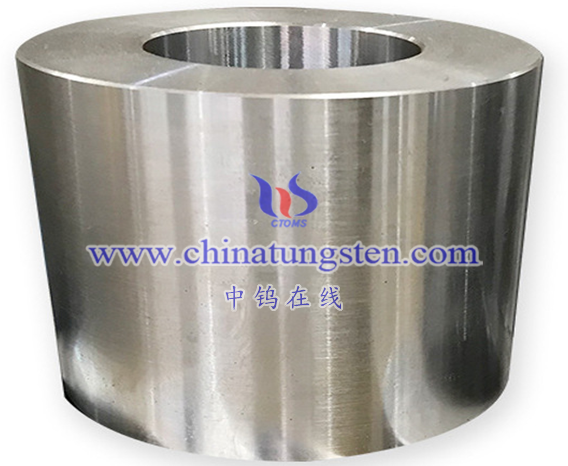

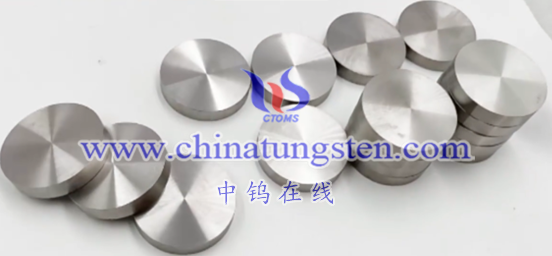

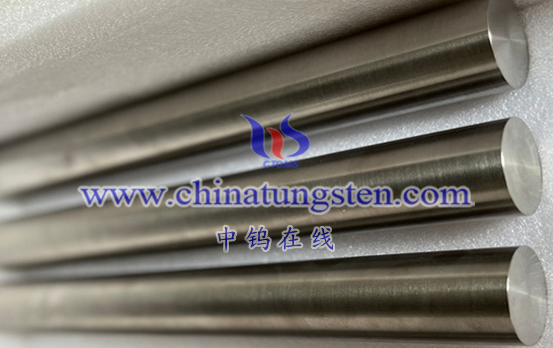

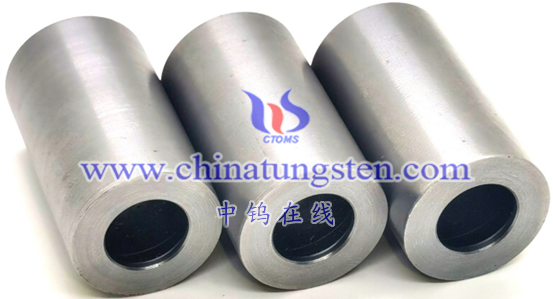

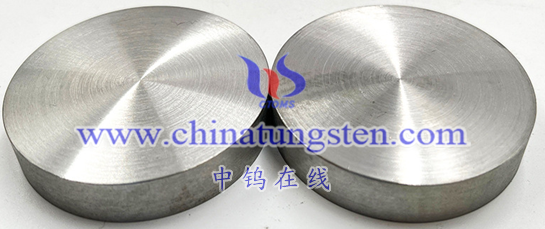

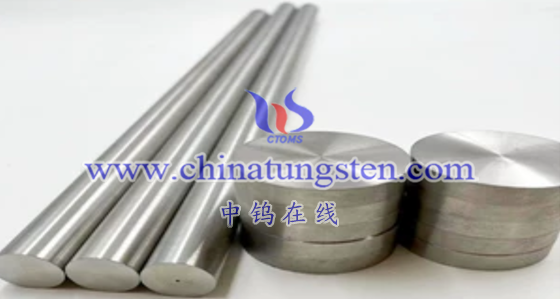

As a high-performance alloy material, tungsten-molybdenum-nickel-iron alloy has significant application advantages in the field of bearing manufacturing. This alloy is mainly composed of elements such as tungsten, molybdenum, nickel and iron. It is produced through a precise powder metallurgy process, which gives it excellent physical and chemical properties and is very suitable as a bearing material.

Tungsten-molybdenum-nickel-iron alloy bearing material has the following characteristics:

High melting point and high temperature resistance

Tungsten-molybdenum-nickel-iron alloy has a very high melting point, usually over 3000 degrees Celsius, which gives it excellent stability and heat resistance in high-temperature environments. Therefore, it is particularly suitable for use in high-temperature processes and high-temperature environments, such as aerospace, energy, chemical industry and other fields.

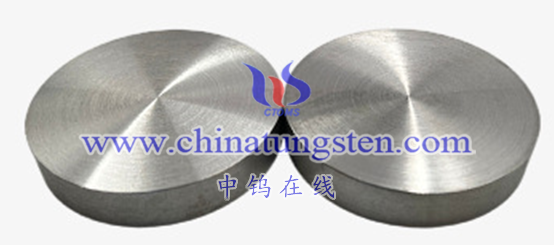

High density and high specific gravity

The density of tungsten-molybdenum-nickel-iron alloy is relatively high, about 18-19 g/cm3, which makes it an ideal high-density alloy material. Due to its high-density properties, it is widely used in manufacturing heavy equipment, vibration eliminators, aerospace components, etc.

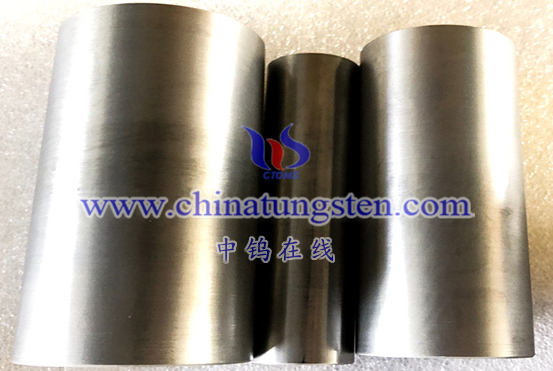

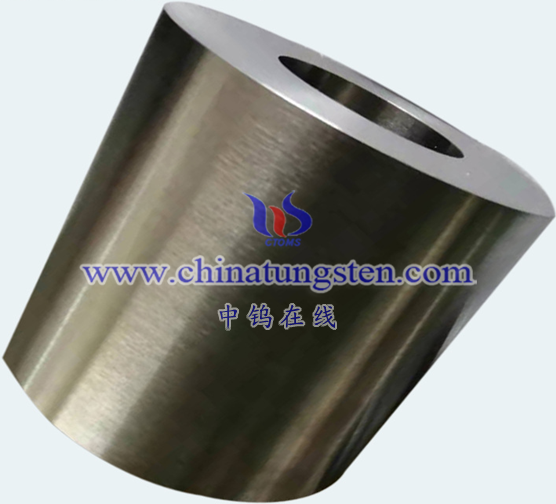

High hardness and wear resistance

Due to the extremely high hardness of tungsten, tungsten-molybdenum-nickel-iron alloy also exhibits excellent hardness and wear resistance. It resists wear, scratching and corrosion, making it ideal for use in the manufacture of cutting tools, abrasives, molds and more.

Good corrosion resistance

Tungsten-molybdenum-nickel-iron alloy has good corrosion resistance and can resist the erosion of many chemical media, including acids, alkalis, salts, etc. This makes it widely used in chemical industry, petroleum, marine engineering and other fields.

Excellent mechanical properties

The alloy’s high strength, toughness and excellent tensile properties make it ideal for manufacturing highly loaded components and structural materials.

Good thermal and electrical conductivity

Tungsten-molybdenum-nickel-iron alloy has good thermal and electrical conductivity, which helps maintain the stability of the bearing and extend its service life under high-temperature operating conditions.

Low vapor pressure and excellent thermal stability

The alloy has low vapor pressure and excellent thermal stability, which allows it to maintain stable performance in high-temperature applications.

These characteristics make tungsten-molybdenum-nickel-iron alloy bearing materials have broad application prospects in many fields, especially in situations that need to withstand high temperatures, heavy loads, high-speed operations and harsh working environments.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595