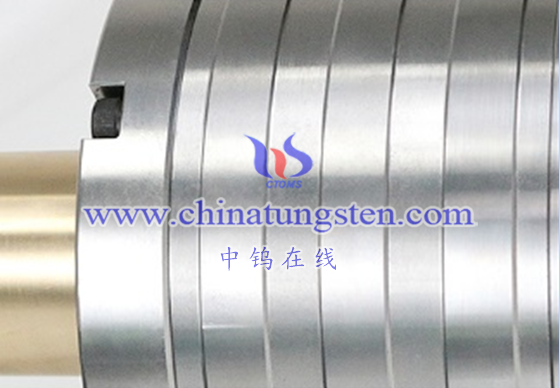

90WMoNiFe alloy cold runner system is suitable for some specific injection molding applications, especially in applications that need to withstand high temperatures, high pressures and corrosive environments. Here are some injection molding application types suitable for use with tungsten molybdenum nickel iron cold runner systems:

High temperature injection molding

Because 90WMoNiFe alloy has excellent high-temperature stability, it is particularly suitable for applications that require injection molding at high temperatures. For example, some engineering plastics (such as PEEK, PI, etc.) need to be fully flowed and formed at high temperatures. In this case, the use of 90WMoNiFe alloy cold runner system can ensure the stability and durability of the runner.

High pressure injection molding

In some injection molding applications, higher injection pressures are required to achieve precise molding and detail. The 90WMoNiFe alloy cold runner system can withstand high pressure without being easily deformed or damaged, ensuring the stability of the mold and the accuracy of the product.

corrosive plastic molding

Some plastic materials will release corrosive substances during the injection molding process, causing damage to the runner part of the mold. 90WMoNiFe alloy has good corrosion resistance to a variety of chemicals, so it is suitable for the molding of these special plastics, such as certain fluorine-containing plastics or special alloy plastics.

long lead production

For applications that require long-term continuous production, the high durability and long life of the 90WMoNiFe alloy cold runner system can significantly reduce the frequency of mold maintenance and replacement and improve production efficiency.

Applications with high product quality requirements

The 90WMoNiFe alloy cold runner system can provide a more stable and uniform plastic flow, helping to reduce product defects and improve product quality. This is especially important for products that require high precision and consistency.

Although the 90WMoNiFe alloy cold runner system is suitable for the above-mentioned application types, factors such as product structure, material properties, and molding process need to be considered when making specific selections. In addition, the cost of 90WMoNiFe alloys is relatively high, so their performance advantages and economics should be considered to determine whether they are suitable for a specific application.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595