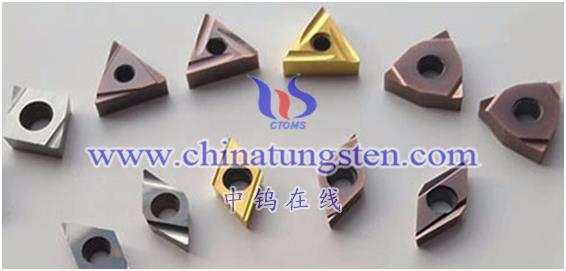

Carbide inserts have the following advantages in precision cutting:

- High hardness and high wear resistance: Carbide blades have high hardness and high wear resistance, which can maintain long-term cutting performance and tool life, thereby improving processing accuracy and efficiency.

- High stability and high precision: Carbide inserts have high stability and high precision, which can reduce vibration and errors during the cutting process, thereby obtaining better surface quality and more accurate processing dimensions.

- Strong ability to cut high-temperature alloys: Carbide inserts have excellent ability to cut high-temperature alloys and can maintain stable cutting performance and tool life under high-temperature and high-speed cutting conditions, thus improving processing efficiency and quality.

- Good impact and vibration resistance: Carbide inserts have excellent impact and vibration resistance, which can maintain stable cutting performance and tool life under strong cutting and intermittent cutting conditions, thus improving processing efficiency and quality. .

- Wide processing range: Carbide blades can process various metal materials, such as steel, iron, copper, aluminum, etc., and can also process various difficult-to-machine materials, such as high-temperature alloys, titanium alloys, stainless steel, etc., thus expanding the Processing range.

To sum up, cemented carbide inserts have the advantages of high hardness and high wear resistance, high stability and high precision, strong ability to cut high-temperature alloys, good impact resistance and vibration resistance, and a wide range of processing in precision cutting. Therefore, it has been widely used in precision cutting.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595