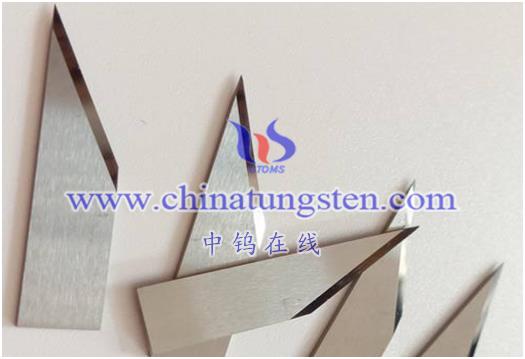

The steps for cutting carbide inserts do not have a fixed process, as they will be appropriately adjusted according to different materials and processing needs. However, the following are general cutting steps:

- Install the carbide insert on the machine or equipment used for cutting.

- Adjust the angle and size of the carbide insert according to the type and hardness of the material to be processed.

- Select appropriate cutting speed and feed rate for cutting. Generally speaking, the faster the cutting speed and the slower the feed speed, the better the cutting effect can be obtained.

- Start cutting and cool the carbide insert as needed to prevent the insert from overheating and affecting its service life.

- After finishing cutting, conduct a quality inspection on the machined surface to ensure that it meets the requirements.

The above are the basic steps for carbide insert cutting. During specific operations, it is recommended to consult professionals to ensure safety and effectiveness.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595