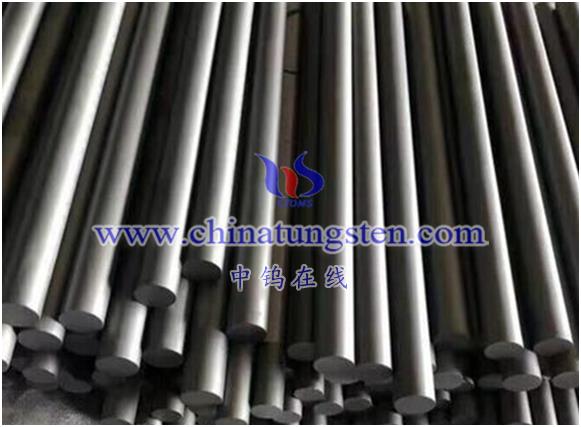

Cemented carbide rod refers to a composite material composed of a refractory metal compound (hard phase) and a bonding metal (binder phase) produced through a powder metallurgy process. In cemented carbide rods, metals such as tungsten (W) and cobalt (Co) are usually used as bonding phases to increase the strength and wear resistance of the alloy.

Carbide rod is a material with high hardness, high wear resistance, high strength and corrosion resistance, and has high application value. It is mainly used in the manufacturing of cutting tools, mining tools, oil drilling tools, chemical equipment and other fields. In addition, carbide rods can also be used to manufacture high-speed steel, carbide cutting tools, molds, bearings and other mechanical parts.

Powder metallurgy is the main process for manufacturing cemented carbide rods. Alloy rods are made by mixing metal powder, ball milling, pressing, sintering and other steps. With the continuous advancement of science and technology, the manufacturing process of cemented carbide rods is also constantly improving, making its application range more and more extensive.

In short, cemented carbide rods are materials with high hardness, high wear resistance, high strength and corrosion resistance, and are widely used in fields such as machinery manufacturing and chemical industry. With the continuous development of science and technology, its application prospects will become increasingly broad.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595