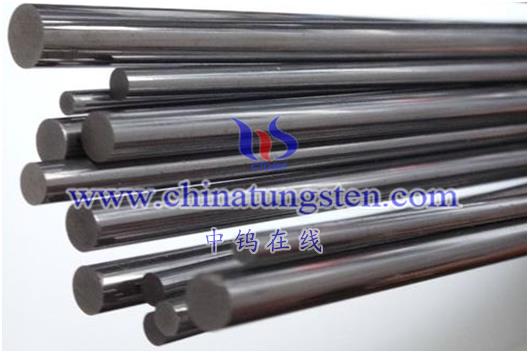

Wear-resistant alloy rods are mainly used to manufacture wear-resistant parts, such as nozzles, coal cutter picks, etc. These parts need to work in harsh environments such as strong corrosion, severe wear, high temperature and high pressure, so they need to have high wear resistance, high hardness, high strength and other characteristics.

For example, in the mining industry, wear-resistant alloy rods can be used to make mining machine picks to improve mining efficiency; in the chemical industry, wear-resistant alloy rods can be used to make equipment such as mixers to improve the corrosion resistance and durability of the equipment. Wear resistance; in the transportation industry, wear-resistant alloy rods can be used to manufacture wear-resistant parts of vehicles to improve the durability and reliability of vehicles.

In short, wear-resistant alloy rods are suitable for use in the manufacture of various wear-resistant parts that require high wear resistance, high hardness, and high strength.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595