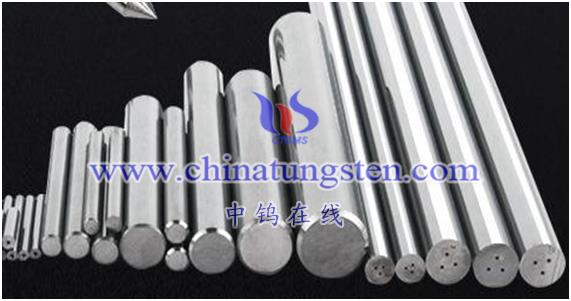

The manufacturing process of cemented carbide single straight hole round rod mainly includes the following steps:

- Powdering: Prepare cemented carbide raw material powder to obtain a plastic mixed slurry.

- Formulation according to application requirements: According to the requirements of different uses and specifications, the prepared mixed slurry is formulated to meet the subsequent pressing and sintering requirements.

- Wet grinding: Wet grind the formulated mixed slurry to refine the powder and improve the quality of pressing and sintering.

- Mixing: Mix the wet-milled powder to make each component evenly distributed to improve the performance of cemented carbide rods.

- Crush: Crush the mixed powder to make the powder finer, which is beneficial to the process of pressing and sintering.

- Drying: Dry the crushed powder to remove moisture and volatile components and improve the stability and pressing quality of the powder.

- Sieving: Sieve the dried powder to remove impurities and irregular particles to ensure the smooth progress of the pressing and sintering process.

- Granulation: The sieved powder is granulated into particles with a certain shape and size, which is beneficial to the process of pressing and sintering.

- Pressing: The granulated particles are pressed to form carbide bar blanks with certain shapes and specifications.

- Forming: Shape the pressed carbide rod blank to obtain the carbide rod with the required shape and specifications.

- Flaw detection inspection: Carry out flaw detection inspection on the formed carbide rods to check whether there are defects and damage on the surface and inside to ensure the quality of the product.

- Cylindrical grinding: Carbide rods that have passed the flaw detection inspection are subjected to cylindrical grinding to remove unevenness on the surface layer, improve surface roughness and parallelism, and meet the needs of different fields.

- Detection size: Detect the size of the ground cemented carbide rod to check whether the size meets the requirements and record it.

- Packaging and warehousing: Carbide rods that have passed the inspection will be packaged and warehousing for subsequent use.

These steps are the main links in the manufacturing of cemented carbide single straight hole round rods. The sequence and operation details between the steps may vary due to different manufacturers and products of different specifications. In the actual production process, it needs to be determined according to the specific circumstances. Make adjustments and optimizations.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595