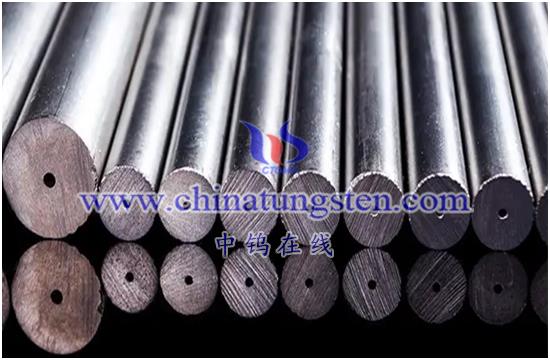

Tungsten carbide round rods have the following application advantages in manufacturing cutting tools:

- High hardness and high wear resistance: The hardness of tungsten carbide round rods is as high as HRA90 or above. It has extremely high hardness and wear resistance. It can cut workpiece materials of various hardnesses, and its service life is far longer than that of other ordinary material cutting tools. .

- High thermal conductivity and high thermal stability: Tungsten carbide round rods have good thermal conductivity and can maintain high hardness and strength at high temperatures. They can be used to manufacture cutting tools that can maintain good performance in various high-temperature environments.

- High density and low thermal expansion coefficient: Tungsten carbide round rods have high density and small thermal expansion coefficient, and can be used to manufacture high-precision mechanical parts and electronic devices.

- Good corrosion resistance: Tungsten carbide round rods have good corrosion resistance in various chemical media and can be used in various corrosive environments.

- Good processability and customizability: The manufacturing and processing process of tungsten carbide round rods is relatively easy, and the size can be customized according to actual needs to meet different application scenarios and needs.

In summary, tungsten carbide round rods have excellent application advantages in manufacturing cutting tools and can be widely used in manufacturing high-precision, high-wear-resistant, and high-performance tools and equipment. However, it should be noted that the manufacturing cost of tungsten carbide round rods is relatively high, so its cost-effectiveness needs to be considered when using it.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595