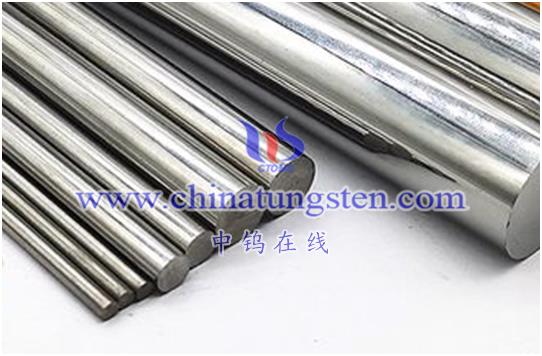

There may be some differences in the composition of tungsten carbide round rods for different uses.

Generally speaking, tungsten carbide round rods are mainly composed of tungsten and carbon, of which tungsten is the main metal component and carbon is added to tungsten as an alloying element. Depending on the purpose, some other alloying elements may be added to the tungsten carbide round rod to improve its performance.

For example, for some applications that require high hardness and wear resistance, such as making cutting tools, some alloying elements such as cobalt and nickel can be added to the tungsten carbide round rod to increase its hardness and wear resistance. For some applications that require high toughness and impact resistance, such as manufacturing structural parts, some alloying elements such as iron and chromium can be added to the tungsten carbide round rod to increase its toughness and impact resistance.

It should be noted that the difference in composition of tungsten carbide round rods for different uses should be determined according to the specific uses and usage requirements. At the same time, since tungsten carbide round rods are an expensive material, waste should be reduced and reused as much as possible.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595