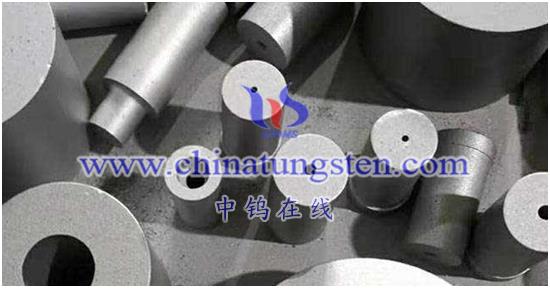

Wear-resistant carbide small cylinders have a wide range of application scenarios and can be used in the following fields:

- Mining machinery: Mining machinery is one of the most important application fields of wear-resistant cemented carbide small cylinders, such as wear-resistant parts in mining ball mills, excavators, rock drills and other equipment, such as pistons, lining plates, tooth plates, etc. , it is necessary to use small wear-resistant carbide cylinders with high wear resistance to improve equipment performance and service life.

- Cement machinery: Key components in cement machinery, such as mills, mixers, crushers, etc., need to withstand high loads and strong friction and wear. Therefore, wear-resistant carbide small cylinders need to be used to manufacture high-performance wear-resistant parts. parts to improve equipment productivity and reduce maintenance costs.

- Petrochemical machinery: Valves, pipes, pump bodies, mixers and other equipment in petrochemical machinery require corrosion-resistant, high-temperature-resistant and wear-resistant materials to manufacture key parts. Wear-resistant carbide small cylinders are among them. An ideal choice.

- Automobile manufacturing: Key parts such as engines, chassis, and suspension systems in automobile manufacturing require the use of high-strength, high-wear-resistant materials to manufacture parts. Wear-resistant carbide small cylinders can meet these requirements and improve the performance of the automobile. performance and longevity.

- Railway locomotives: Key parts such as wheels, bearings, and brake systems in railway locomotives require materials with high wear resistance and high stability to manufacture parts. Wear-resistant carbide small cylinders are one of the ideal choices. .

In summary, wear-resistant cemented carbide small cylinders are widely used in mining machinery, cement machinery, petrochemical machinery, automobile manufacturing, railway locomotives and other fields. They are a high wear-resistant material with important application value. In addition to the above application fields, wear-resistant carbide small cylinders can also be used in the following fields:

- Mechanical processing: Wear-resistant carbide small cylinders can be used to manufacture cutting tools and cutting tools, such as milling cutters, drill bits, turning tools, etc. They can withstand high-speed rotation, stress, etc., and achieve good cutting effects and service life.

- Manufacturing of wear-resistant parts: Wear-resistant carbide small cylinders can be used to manufacture various wear-resistant parts, such as seals, bearings, gears, etc., which can effectively improve the wear resistance and service life of these parts.

- Geological exploration: Wear-resistant cemented carbide small cylinders can be used to manufacture geological drill bits and wear-resistant parts. They can withstand high-intensity impact and wear during geological exploration and improve drilling efficiency and accuracy.

- Electronic communications: Wear-resistant carbide small cylinders can be used to manufacture wear-resistant parts of electronic communications equipment, such as base stations, switches, etc., which can effectively improve the stability and service life of these equipment.

- Construction field: Wear-resistant carbide small cylinders can be used to manufacture wear-resistant materials for construction, such as building formwork, scaffolding, etc., which can improve the corrosion resistance and service life of these equipment.

To sum up, wear-resistant cemented carbide small cylinders have a wide range of applications and can improve the durability and production efficiency of various mechanical equipment, and increase the service life and stability of the equipment.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595