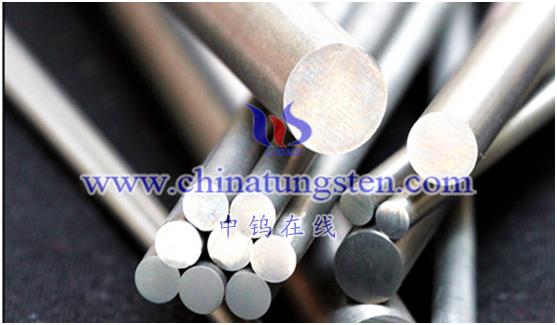

Super-hard wear-resistant high-precision tungsten carbide rods are mainly used in the following fields:

- Cutting tool field: Due to its extremely high hardness and wear resistance, tungsten carbide rods can be used to manufacture various cutting tools, such as drills, milling cutters, turning tools, planers, crankshafts, gears and ball screws, etc., which can improve Processing efficiency and precision, reducing production costs.

- Wear-resistant parts: Because tungsten carbide rods have good wear resistance and bending resistance, they can be used to manufacture various wear-resistant parts, such as small-diameter micro drills, tools for watch processing, and integral reamers.

- Electronic field: Because tungsten carbide rods have good electrical conductivity and thermal stability, they can be used to manufacture various electronic components, such as metal oxide semiconductor field effect transistors (MOSFETs), silicon controlled rectifiers, etc.

- Special application fields: Tungsten carbide rods can also be used in some special fields, such as manufacturing high-temperature coatings, electronic materials, optical materials, etc., and as manufacturing materials for small tools and equipment such as micro drills.

In short, super-hard wear-resistant and high-precision tungsten carbide rods are widely used in metal processing, wear-resistant parts, electronics and other fields, and have made important contributions to the production and technological development of various industries.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595