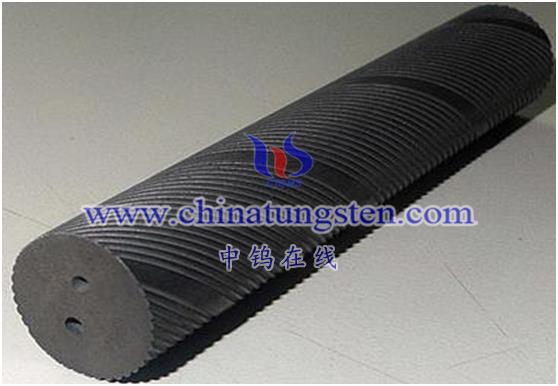

Super-hard wear-resistant high-precision tungsten carbide round rods are mainly used in the following scenarios:

- Cutting tools: Tungsten carbide round rods can produce high-precision cutting tools, such as turning tools, milling cutters, drill bits, etc., which can significantly improve cutting efficiency and extend the service life of the tools.

- Wear-resistant parts: Because tungsten carbide round rods have extremely high wear resistance and bending resistance, they can be used to manufacture various wear-resistant parts, such as integral reamers, micro drills, etc.

- High-temperature resistance components: Tungsten carbide round rods have excellent high-temperature stability, so they can be used to manufacture high-temperature resistance components, such as nozzles, thermocouple sleeves, etc.

- Electronic devices: Tungsten carbide round rods have good electrical conductivity and thermal stability and can be used to manufacture various electronic devices, such as thermally conductive substrates in electronic packaging, electronic cutters, etc.

- Special application scenarios: Tungsten carbide round rods can also be used in some special fields, such as abrasives and polishing agents for superhard materials, as well as in high-end manufacturing in aerospace, military and other fields.

It should be noted that the manufacturing and use of tungsten carbide round rods require strict control of process parameters and quality standards to ensure their excellent performance and reliability. At the same time, severe shock and vibration should be avoided during use to prevent cracks and damage.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595