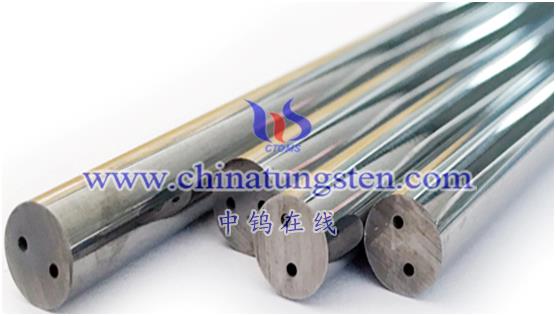

Tungsten steel round rod with holes is an alloy material made of cemented carbide tungsten steel (WC) as the main raw material, plus cobalt powder, chromium carbide and other other ingredients, and is pressed and sintered by powder metallurgy. It has the characteristics of high hardness, high strength, high wear resistance and high corrosion resistance, and is widely used to manufacture various high-precision, high-wear-resistant tools, molds and parts.

Compared with ordinary tungsten steel round bars, some special processes and materials are added to the tungsten steel round bars during the manufacturing process, which makes them have better wear resistance and corrosion resistance, and also improves the strength and strength of the material. toughness.

The manufacturing process of tungsten steel round rods with holes mainly includes the following steps:

- Ingredients: Mix tungsten steel powder, cobalt powder, chromium carbide and other raw materials evenly according to a certain proportion.

- Pressing: Press the mixed materials into shape and send them to the sintering furnace.

- Sintering: The pressed blank is sintered at high temperature into a tungsten steel perforated round rod with the required shape and properties.

- Processing: Process the sintered tungsten steel round rod with holes, such as turning, milling, drilling, etc., to achieve the required size and shape.

It should be noted that the manufacturing process of tungsten steel round rods with holes also involves many details and process controls, such as sintering temperature, sintering time, pressing pressure, etc. These factors will affect the performance and quality of the final product.

In addition, the application of tungsten steel round rods with holes also needs to be reasonably selected and used according to specific working conditions and usage requirements. For example, appropriate materials and processing techniques should be selected according to the load, rotation speed, impact and other parameters that need to be endured to ensure that It can meet the usage requirements and achieve the best service life.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595