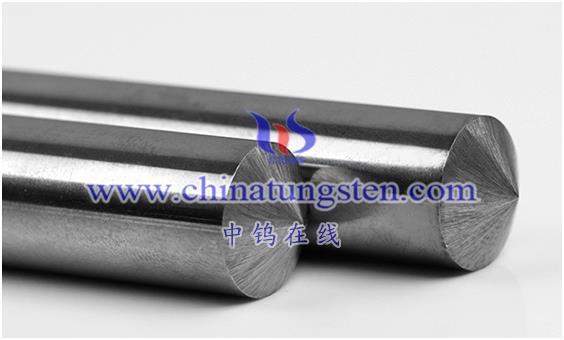

Tungsten steel round bars are widely used in machinery manufacturing. Here are some common applications:

- Tools and cutting tools: Because tungsten steel round bars have high hardness and high wear resistance, they can be used to manufacture various cutting tools and cutting tools, such as turning tools, milling cutters, planers, drill bits, end mills, reamers, etc. , used for cutting various metal and non-metal materials.

- Wear-resistant parts and tools: The wear resistance and high strength of tungsten steel round rods make it an ideal material for manufacturing wear-resistant parts and tools, such as rock drilling tools, mining tools, drilling tools, measuring measuring tools, and wear-resistant parts. , metal grinding tools, etc.

- High-temperature parts: Tungsten steel round rods have excellent high-temperature properties and can maintain their hardness and strength at high temperatures. Therefore, they can be used to manufacture parts in high-temperature environments, such as cylinder liners, precision bearings, nozzles, etc.

- Precision manufacturing: Due to the high hardness and precision of tungsten steel round bars, they can be used to manufacture high-precision mechanical parts and components, such as shafts, pins, bolts, etc.

- Bulletproof and other safety purposes: Tungsten steel round rods have high strength and good impact resistance. They can be used to make protective equipment such as bulletproof vests and safety helmets, and can also be used for other safety purposes.

In short, tungsten steel round rods have broad application prospects in machinery manufacturing, and their excellent performance and high reliability make them one of the preferred materials in many machinery manufacturing fields.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595