There are mainly the following types of carbide sawtooth cutting blades:

High-speed steel saw blade (HSS saw blade): This saw blade is one of the most common carbide saw blades, mainly made of tungsten steel series carbide. It is mainly used for metal cutting and has high hardness and high wear resistance.

Diamond saw blade: This saw blade is mainly made of diamond and has very high cutting accuracy and efficiency. It is mainly used for cutting hard materials such as glass, ceramics and stone.

Solid carbide saw blade: This saw blade is made of a solid piece of carbide, has high hardness and high wear resistance, and is suitable for high-speed cutting and processing.

Tungsten steel saw blade: This kind of saw blade is made of tungsten steel series hard alloy. It has high hardness and high wear resistance, and is suitable for cutting metal, wood and other materials.

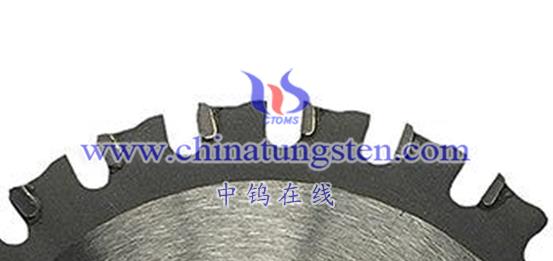

Inlaid alloy saw blade: This kind of saw blade is inlaid with a carbide tip on a carbide base. It has high cutting efficiency and precision and is suitable for cutting various materials.

In addition, depending on the use environment and cutting materials, there are also carbide sawtooth cutting blades with different tooth shapes, such as flat teeth, staggered bevel grinding teeth on the rear tooth surface, one-way bevel grinding teeth on the rear tooth surface, left and right bevel grinding teeth, etc. . At the same time, according to the different needs of customers, carbide saw-tooth cutting blades of different specifications and uses can also be customized.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595