Carbide saw blades are made of carbide. Cemented carbide, also known as tungsten-cobalt alloy, is usually hot-pressed from a powder mixture of tungsten (chemical symbol: W) and cobalt (chemical symbol: Co). Carbide is known for its very high hardness and wear resistance, making it suitable for use in the manufacture of cutting, drilling and grinding tools.

Carbide’s hardness comes primarily from the tungsten particles in it, while cobalt acts as a binder to hold the tungsten particles together into a strong structure. This special combination makes carbide an excellent cutting tool material for a variety of different cutting tasks, including cutting wood, metal, plastic, glass, and other materials.

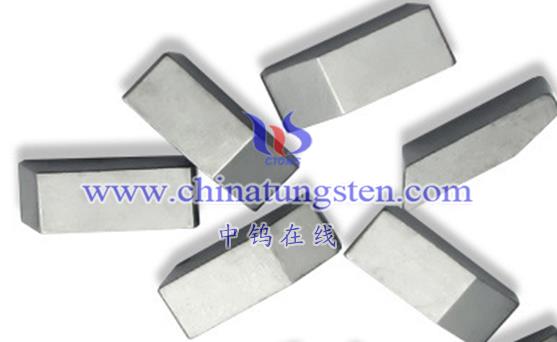

Carbide saw blades usually have carbide teeth or blades attached to their cutting edges to provide better cutting performance and durability. The carbide blades of these saw blades are typically manufactured using a powder metallurgy process, ensuring a strong and wear-resistant cutting edge.

More details of tungsten carbide product, please visit website: http://tungsten-carbide.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595